Typically accomplished through pneumatic conveyors, powder handling can also be done using closed or flexible screw conveyors. Read More…

VAC-U-MAX is a premier custom pneumatic conveyors manufacturer of support equipment for conveying, batching and weighing materials. With our system your company’s product can move gently and quickly from point to point, with nothing in the way to impede the efficiency of its movement. Contact VAC-U-MAX today so they can find the perfect product for you.

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry.

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

At ENTEK, we are a dynamic team of experts specializing in pneumatic conveyors, dedicated to providing innovative solutions that streamline material handling processes for a wide range of industries. With a proven track record of excellence and a commitment to customer satisfaction, we have established ourselves as a trusted partner for clients seeking efficient and reliable conveying solutions....

More Powder Handling Manufacturers

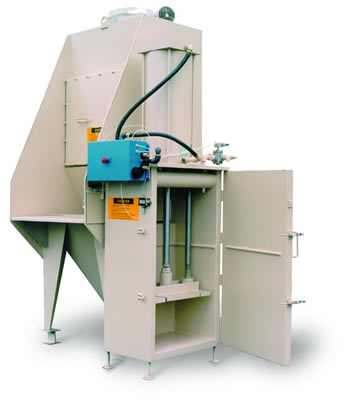

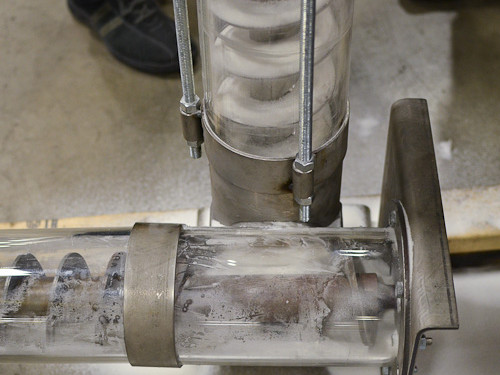

Pneumatic conveyors are particularly advantageous for powder handling applications as a result of their enclosed, tubular design, which reduces product leakage as well as eliminating material and operator contact.

In addition, pneumatic conveyors offer decreased product contamination, which is a problem for screw conveyors since they are more susceptible to incur product damage by caking, smearing, packing, or grinding.

Common powdered solids that are handled using pneumatic conveyors include metals, chemicals, fly ash, flour, and talc.

As pneumatic powder handling is most often used to move materials through manufacturing and processing stages, powder handling conveyors must be able to carefully and efficiently transport powders that could be potentially hazardous.

Due to wide-ranging powder handling applications, diverse industries require powder handling conveyors including pharmaceutical, food and chemical processing, industrial, ceramics, plastics, and construction. However, most pneumatic conveyors are designed to handle specific material types, so different industries will require a different type of conveyor.

For powder handling applications, dilute phase pneumatic conveyors are the most common type of conveyors used. Dilute phase conveying can be done with either pressure or vacuum pneumatic systems, as long as high air velocity is created and maintained. Dilute phase conveying can utilize either positive or negative pressure, although each of these types of systems works best in certain circumstances.

For example, positive-pressure dilute phase conveyors are best suited for conveying materials loaded from a single entry point to one or multiple destinations. Positive-pressure systems can transport materials over a relatively long-distance and use a minimum quantity of air to move the material.

Conversely, negative-pressure dilute phase conveyors work best in transporting powdered materials loaded from numerous inlet points and discharging them at a single point.

In addition, there are a variety of different dilute phase conveyor system designs. A closed-loop dilute phase conveyor uses an inert gas as the conveying medium to convey the powder in a closed-loop system. This type of dilute phase conveying is useful for handling hazardous powdered chemicals. A centrifugal blower dilute phase conveyor can use a combination of pressures or other system designs but use centrifugal blowers in place of positive displacement power packages.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

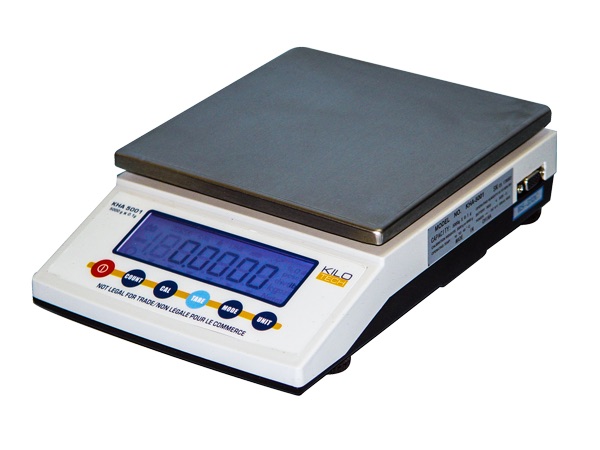

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services