This article contains everything you need to know about vacuum conveyors and their use. Read More…

VAC-U-MAX is a premier custom pneumatic conveyors manufacturer of support equipment for conveying, batching and weighing materials. With our system your company’s product can move gently and quickly from point to point, with nothing in the way to impede the efficiency of its movement. Contact VAC-U-MAX today so they can find the perfect product for you.

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry.

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

At ENTEK, we are a dynamic team of experts specializing in pneumatic conveyors, dedicated to providing innovative solutions that streamline material handling processes for a wide range of industries. With a proven track record of excellence and a commitment to customer satisfaction, we have established ourselves as a trusted partner for clients seeking efficient and reliable conveying solutions....

More Vacuum Conveyor Manufacturers

You will learn:

- What is a Vacuum Conveyor?

- Types of Vacuum Conveyors

- Uses for Vacuum Conveyors

- Materials Transported by Vacuum Conveyors

- And much more …

What is a Vacuum Conveyor?

A vacuum conveyor is a product movement system that relies on the use of suction to create a vacuum for material movement. The forms of vacuum conveyors vary from belt types of conveyors that use suction to keep products on a belt to tube or pipe vacuum conveyors that use a system of pipes and a vacuum pump. The differentiation between the two systems is the types of materials they can move with the belt type able to move fragile lightweight items able to rest on a conveyor belt while a vacuum tube system is used to move powders, granular materials, and liquids.

Vacuum conveying using a pipe system uses negative pressure to move powders and bulk solids to the next step in production, different locations, unload trucks, or for further processing. It is an inexpensive, efficient, and safe method for product handling.

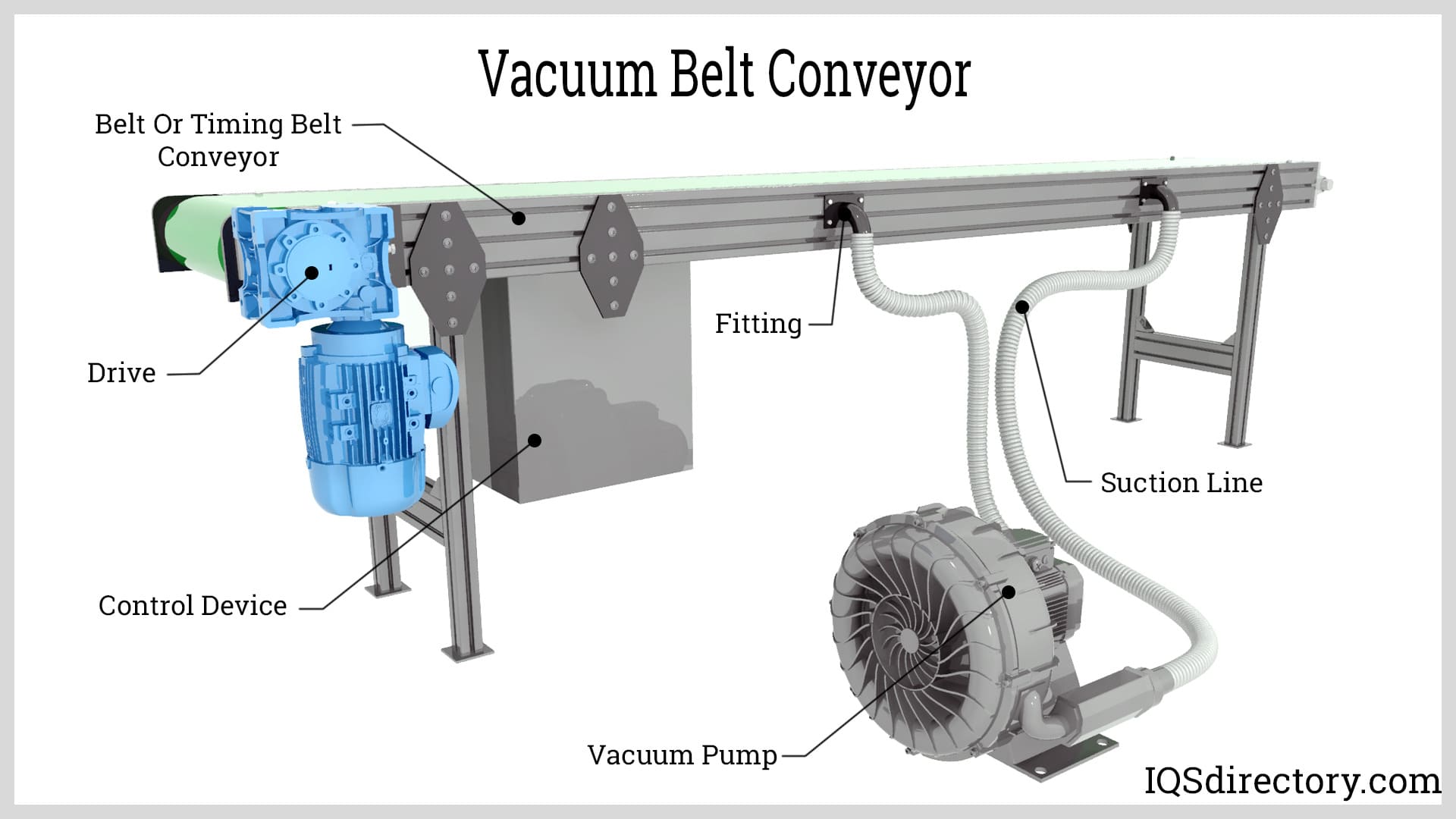

Vacuum belt conveyors work like all forms of belt conveyors but have a perforated surface connected to a vacuum system that causes suction between items on the belt and the belt. They are designed to move materials through high inclines because of the unique gripping mechanism or light materials. Vacuum belt conveyors are widely used for their safety and ability to move an assortment of materials.

Types of Vacuum Conveyors

The tube and belt vacuum conveyors are further divided into different types that are defined by their method for producing a vacuum, the types of materials they move, and the materials from which they are made. The different types of vacuum conveyors are designed to perform specific tasks with the majority of vacuum conveyors being custom designed and configured.

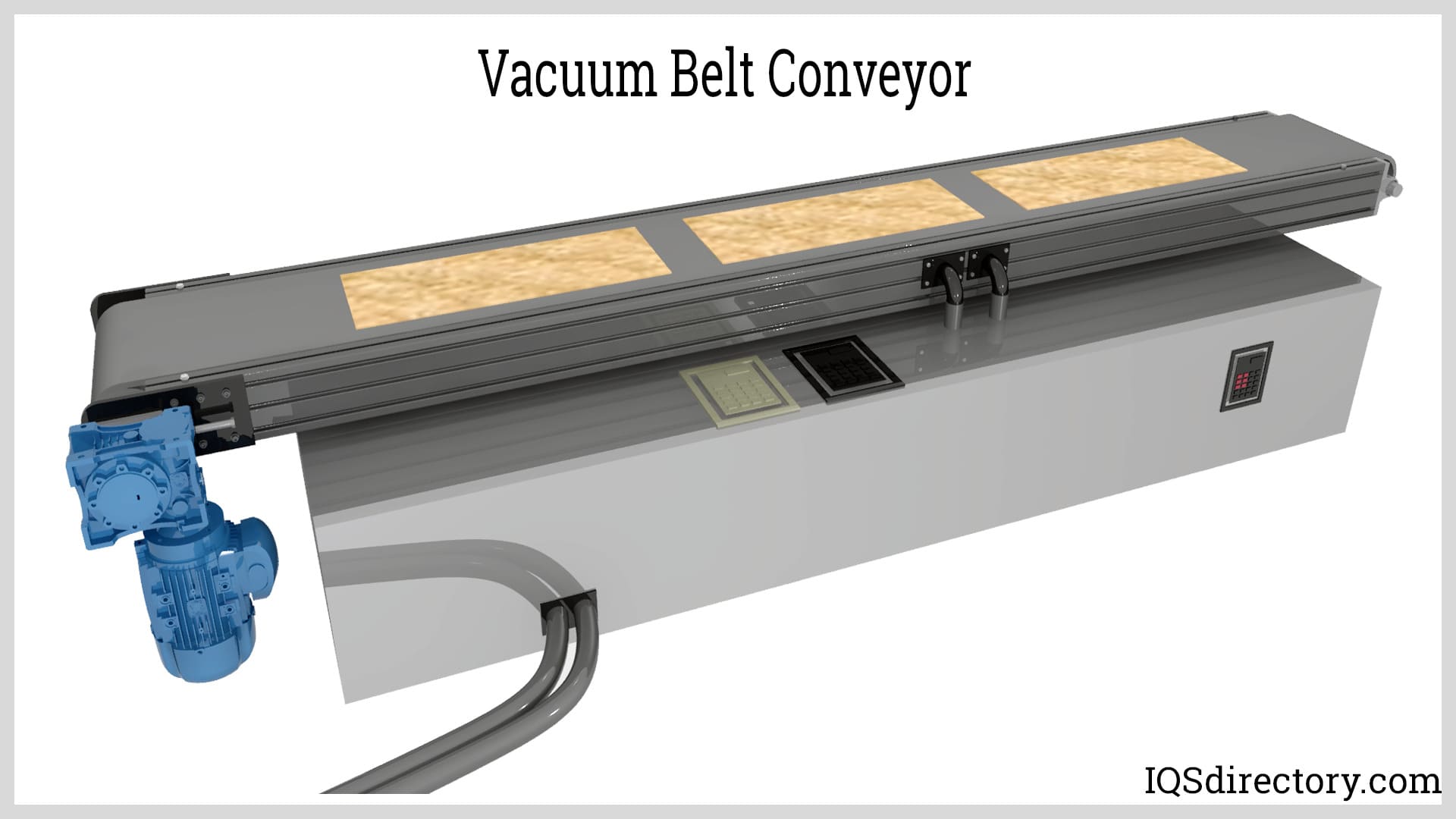

Vacuum Flat Belt Conveyors

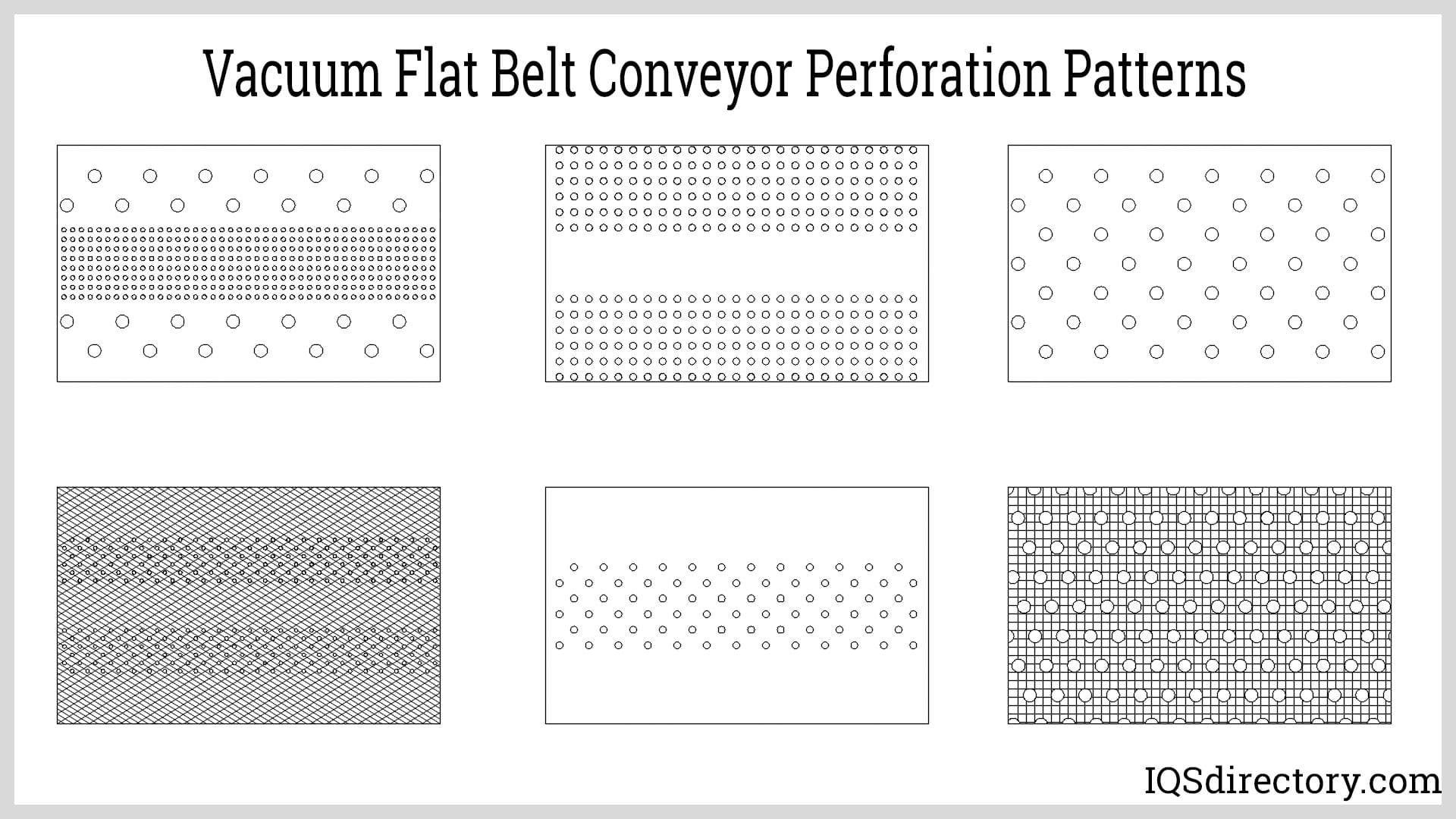

Vacuum flat belt conveyors are an innovative way for dealing with the transport of light materials that would not have sufficient friction to stay on a traditional belt conveyor. Once an item is placed on a vacuum belt conveyor, it remains in a set position for marking, stabilization, or picking. Flat belt vacuum conveyors consist of a perforated belt, vacuum box or plenum, bed plate, and a vacuum pump. The combination of these factors creates the suction that pulls materials down onto the belt.

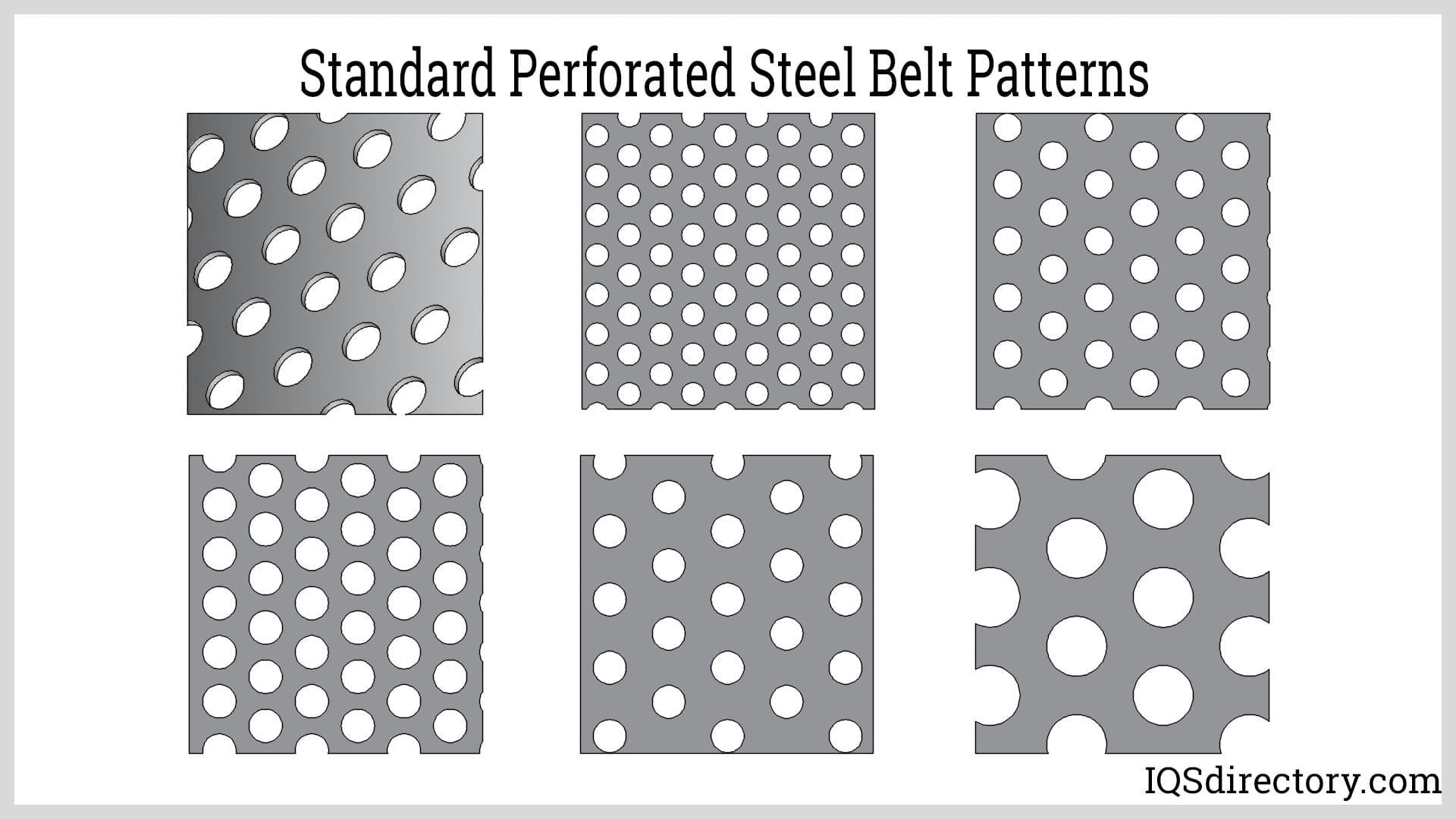

The amount of suction required for the various vacuum flat belt conveyors is determined by the size and dimensions of the perforations, which are determined by the materials that are being transported. Traditionally, more than 30% of the surface of the belt is open. The balance between the size, number, and dimensions of the perforations determines the lifespan of a vacuum flat belt conveyor.

Aside from the initial components of a vacuum flat belt conveyor are the upstream pulley and downstream pulley that move the belt of the conveyor. The belt sets on plating with openings that are connected to the negative pressure source. The upstream portion of the belt is in contact with a curve and perforated guiding surface.

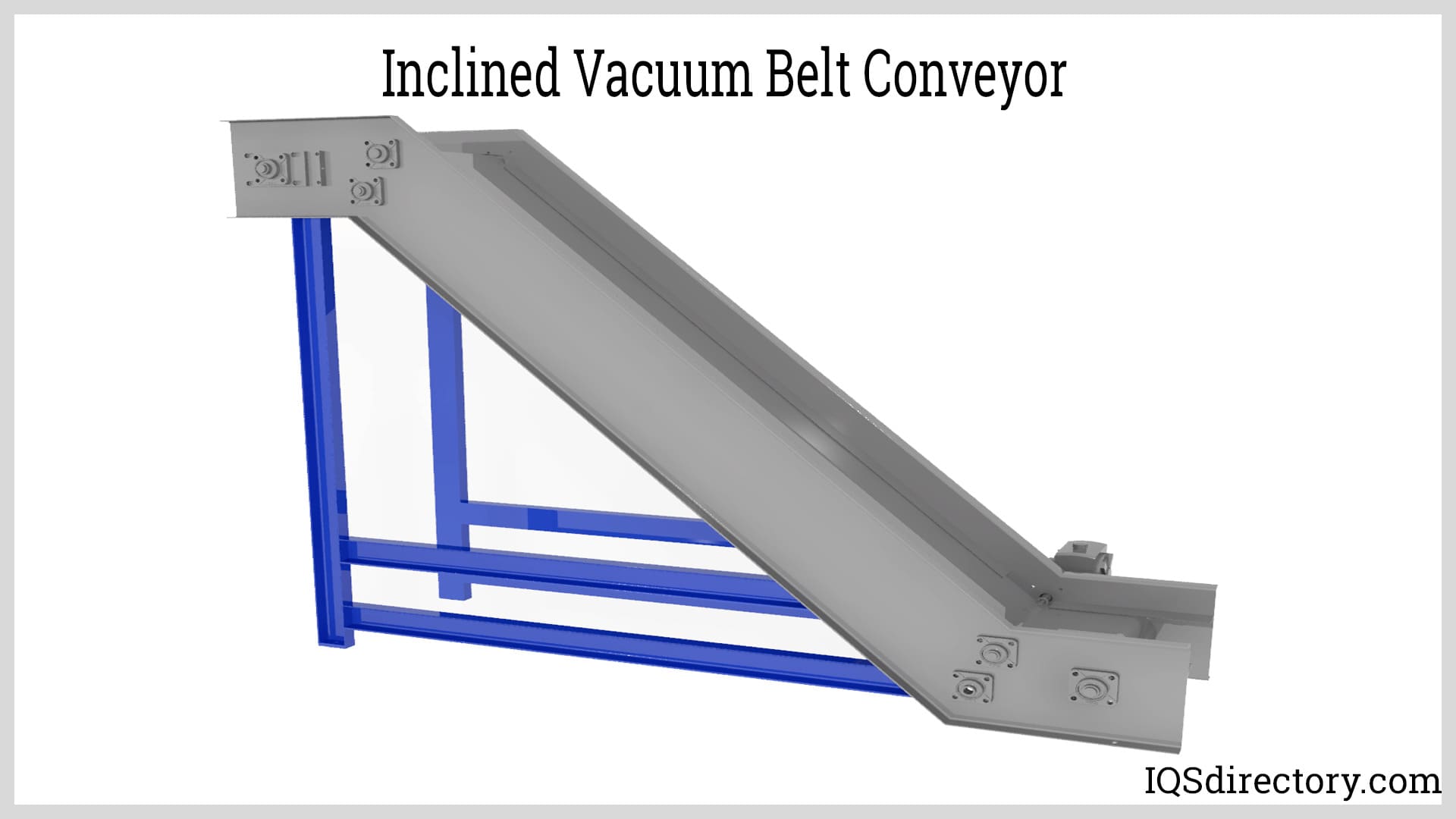

Vacuum Belt Incline Conveyor

The purpose of a vacuum belt incline conveyor is to transfer media between different levels or heights for easy access. Vacuum incline conveyors have the same structure as flatbed vacuum conveyors but are set at an angle. To control the material being moved, vacuum belt incline conveyors have a vacuum at the center of their belt to hold the material in place as it is moved upward. The strong suction and secure hold make it possible for media to be moved rapidly with speeds ranging up to 500 ft/min (152.4 m/min).

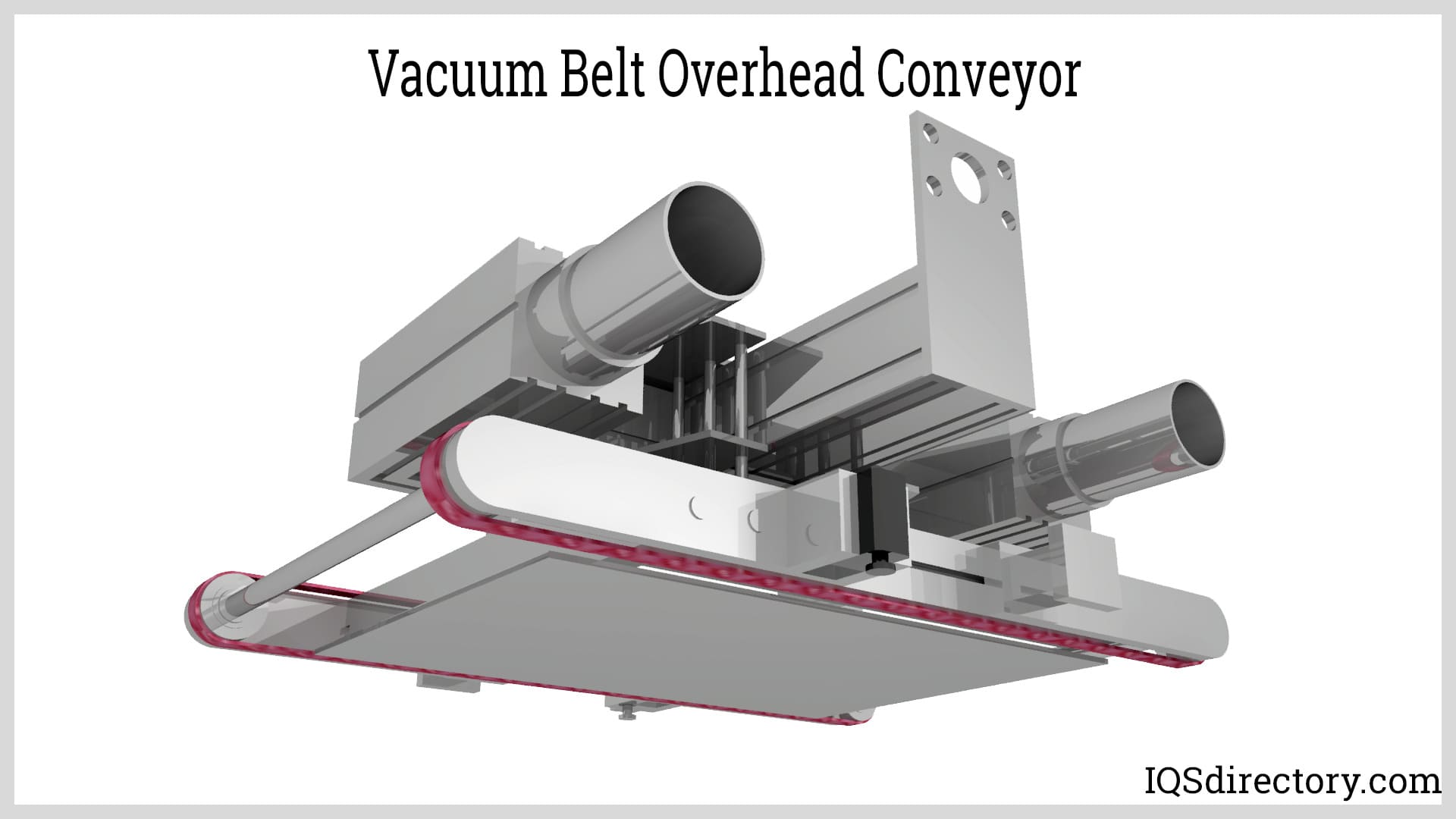

Overhead Vacuum Belt Conveyors

Overhead vacuum belt conveyors are designed for wall mounting for overhead transportation of materials. As with most vacuum belt conveyors, overhead vacuum belt conveyors are designed to move delicate and fragile materials such as plastic film to a production location. The structure of the perforated belts for overhead vacuum conveyors is different from the traditional and common belts for flatbed and incline vacuum conveyors with some versions having a flat belt while other types have belts that look like strips of tape that are a few inches wide.

The design of overhead vacuum conveyors is such that the conveyor operates inverted and moves materials suspended from its lower side. The rail for the conveyor is a vacuum spring loaded against the smooth inner surface of the belt with a vacuum groove for horizontal alignment and holes in the belt attached to vacuum cups. Suspended materials are secured by the vacuum suction of the cups.

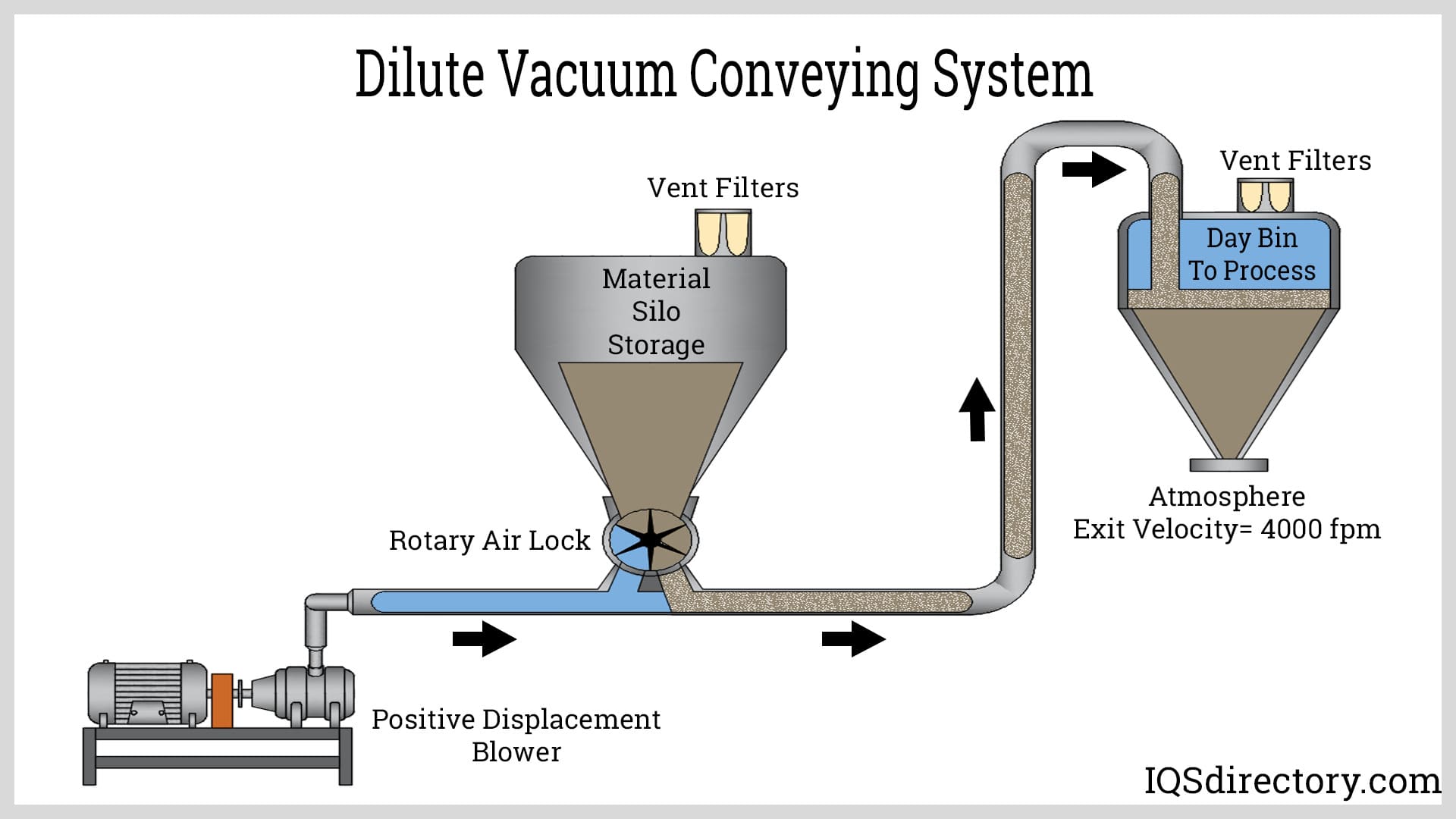

Dilute Phase Vacuum Conveyors

Dilute phase vacuum conveyors are pneumatic conveying systems designed for short distance conveying of various powder materials. The process for dilute phase vacuum conveying is used for the transport of non-abrasive materials that are not fragile and have a low bulk density. As is traditional with all forms of pneumatic conveying systems, materials move along an enclosed sealed pipe in slug form using negative pressure to move material at extremely high velocity and low pressure. The two forms of dilute phase conveying are vacuum and pressure.

Vacuum dilute pneumatic conveying systems have a vacuum velocity of 3500 up to 9000 ft/min (1067 up to 2743 m/min). The vacuum system is used to convey materials that pack or compress under pressure and can be used to move toxic materials. The system operates below atmospheric pressure at -14.7 psi and is referred to as a negative pressure system. It is used to move material from a single source or multiple sources such as trucks, railway cars, stockpiles, and storage bins.

The system for a dilute phase vacuum conveyor uses a positive displacement exhauster that supplies air flow at a constant velocity to move material through a pipeline. During transport, due to the negative pressure, the bulk material is suspended in the airstream while being conveyed. At the receiving end of the transport, the air and material are separated by a cyclone or filtration receiver.

Pull Push Conveying Systems

Pull push conveying systems use a combination of negative and positive pressure systems to convey materials. The system takes advantage of the aspects of negative and positive pressure that are combined into a single transport system. An exhauster blower is used to vacuum and positively pressurize bulk materials. The vacuum pressure combination uses negative pressure to collect material from a source and deliver it to a transfer container from which it is transported using positive pressure.

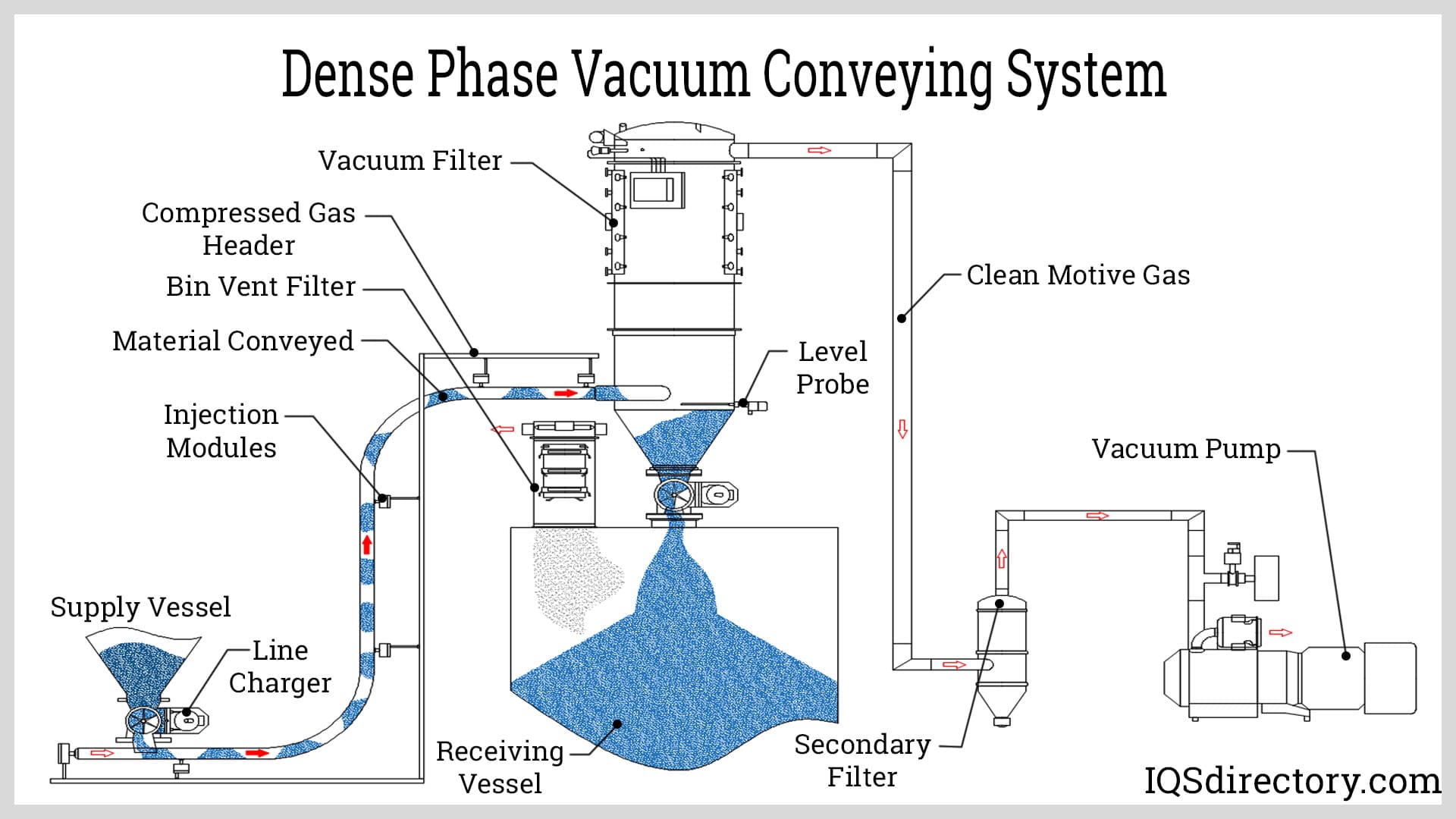

Dense Phase Vacuum Conveyors

Dense phase vacuum conveyors move materials using a controlled vacuum at low velocity and create packets of products in the piping system. The concept is built on the idea of removing stress from the product making it possible for a dense phase vacuum system to transport fragile and delicate products. As with dilute phase vacuum conveyors, they prevent buildup in the piping with the packets or product located close together.

High-capacity vacuum pumps that produce a 99% vacuum are used by dense phase vacuum systems to convey materials. Batches are drawn by a vacuum pump into a vacuum hopper. Once the hopper is full, an isolation valve closes and a discharge valve opens releasing the material in the hopper. Valves and sensors regulate and control the process including the applied vacuum, fluidization settings, and the velocity of product movement.

The small weight of air used to move products transports the material gently through the piping to prevent damage. Unlike the high velocity of dilute phase vacuum conveying, in dense phase vacuum conveying, the material flows in slugs ejected from the hopper. There are pockets of gas between the slugs instead of a continuous stream of a single batch of material.

When dense phase vacuum conveying is used for loading trucks and railway cars, it uses aeration to discharge material into the conveying line. Dense phase vacuum conveying is capable of transporting semi-abrasive and fluidized materials. The use of the system is not advised for large or variable sized particles since particle sizes for the system are restricted to 0.25 in (6.35 mm) or less.

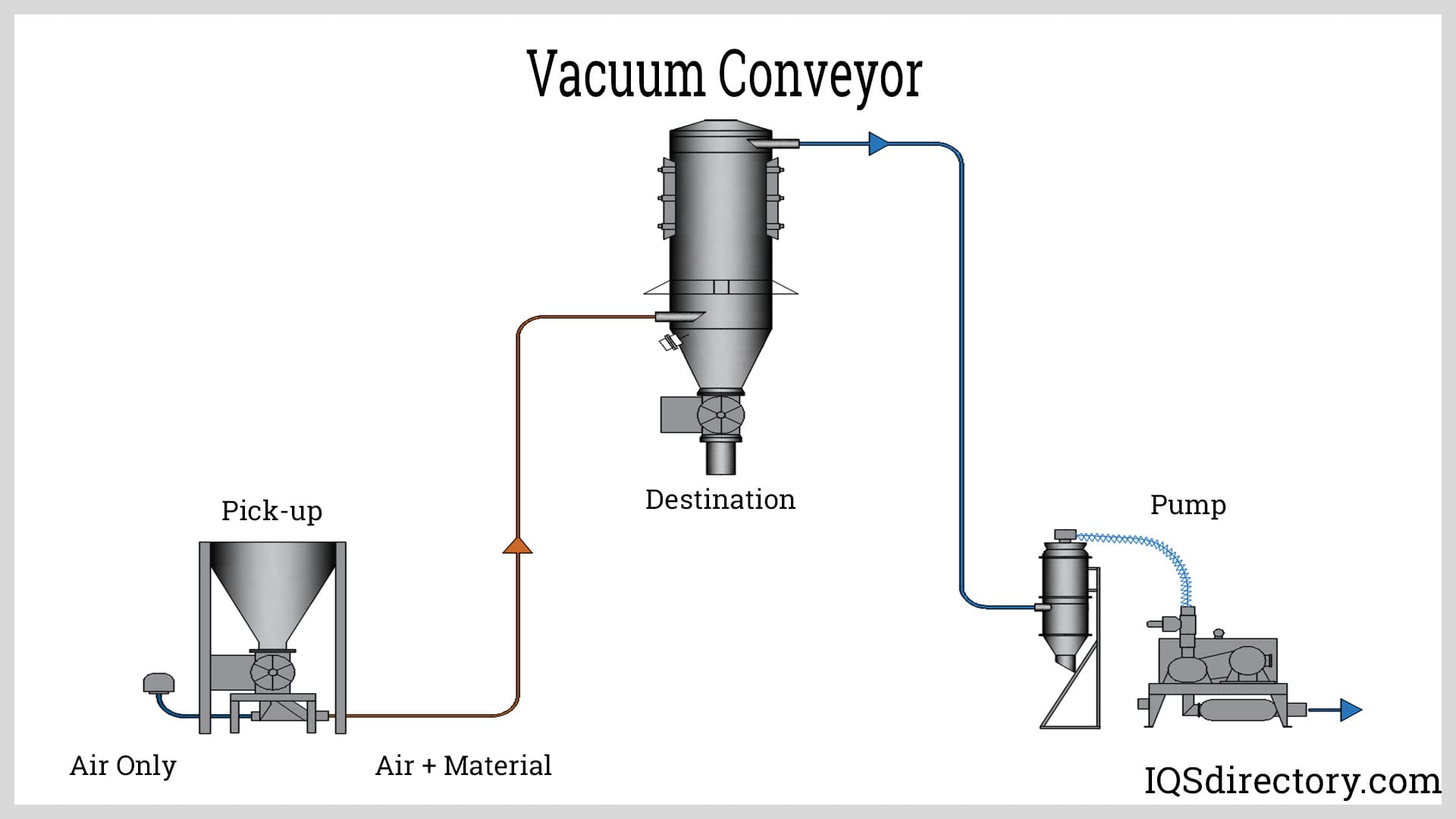

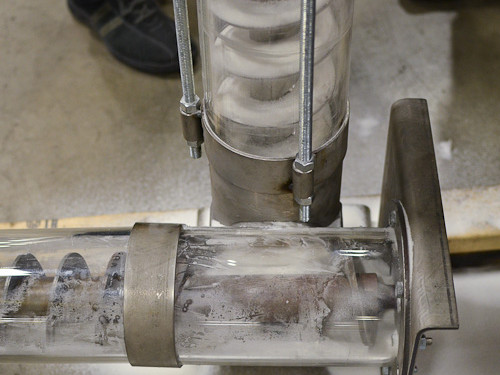

Components of a Pipe Vacuum Conveyor

The two forms of vacuum conveyors use different methods for conveying and transporting products. Vacuum conveyor belts are designed to secure delicate and fragile products for delivery to assembly operations while pneumatic vacuum pipe conveyors are designed to move bulk materials. The unique nature of each process requires a different set of components.

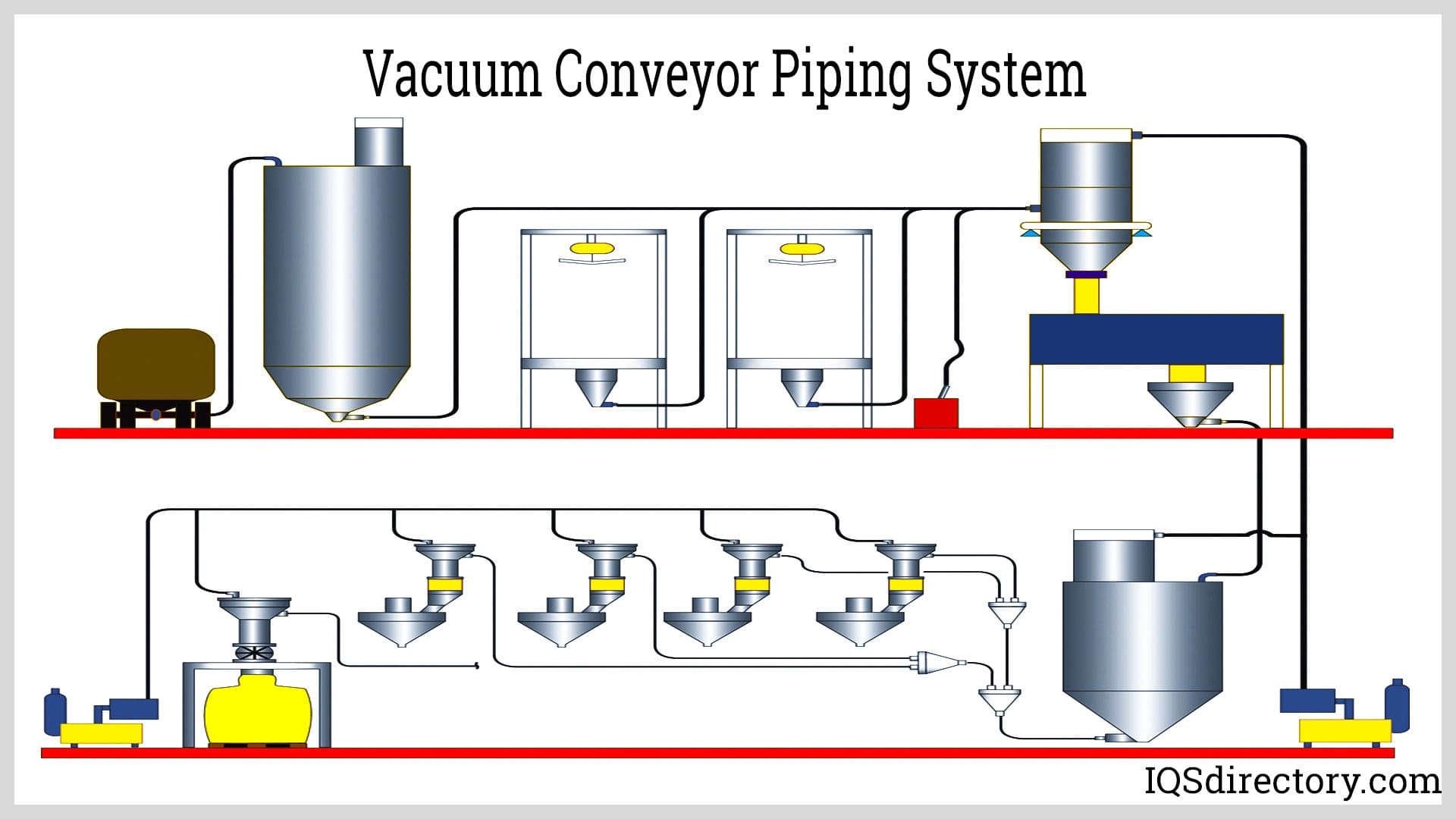

The concept of vacuum pipe conveying is built on the principle of negative pressure and air velocity to transport large quantities of powders and granular products. The key element of a vacuum pipe conveying system is its blower pump that creates the negative pressure to pull product through the system.

Vacuum Pump

The vacuum pump for a vacuum conveying system is placed at the end of the pipeline in order to supply the suction to pull material through the pipeline. The negative pressure created by the vacuum pump is controlled by a relief valve.

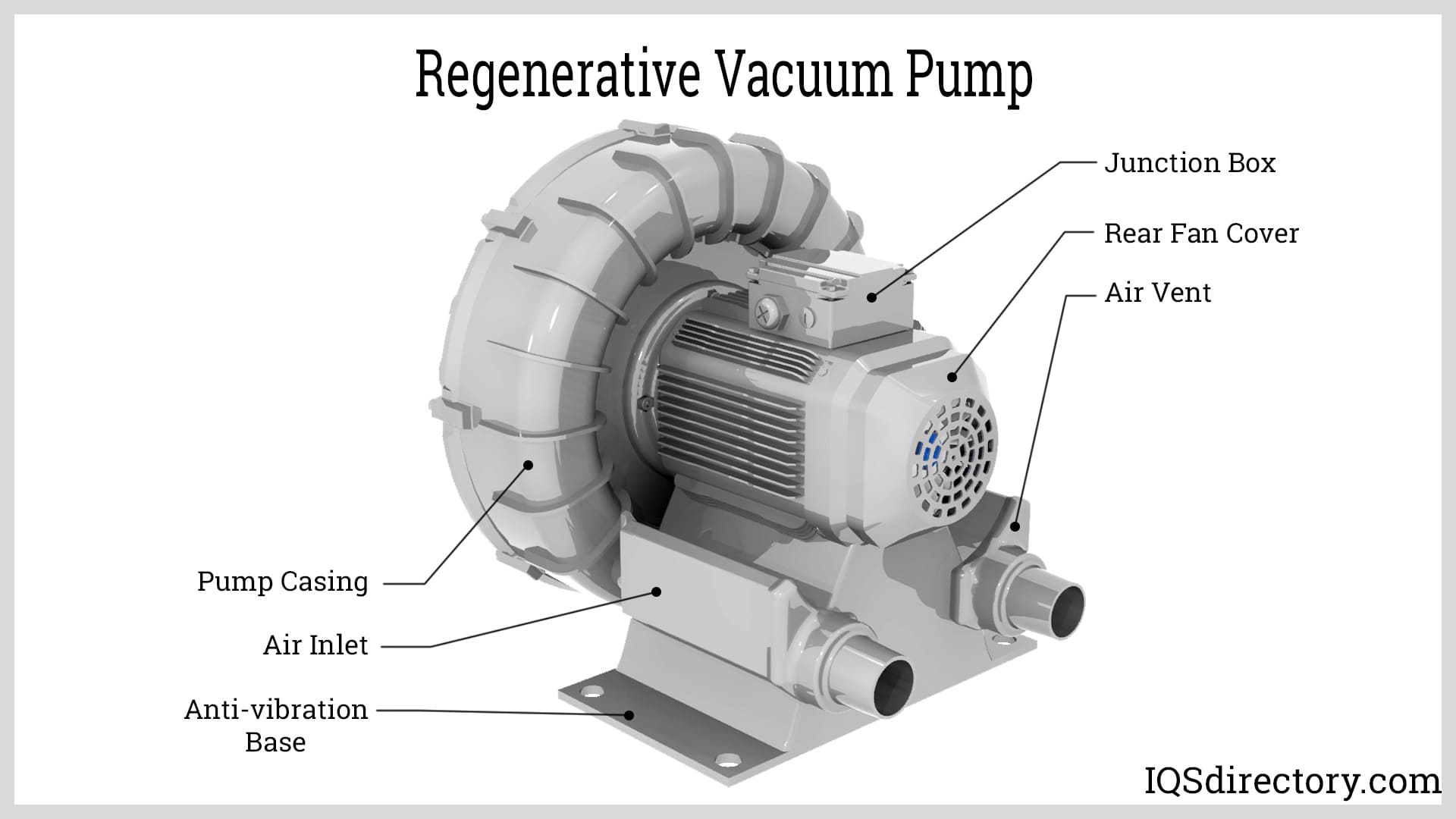

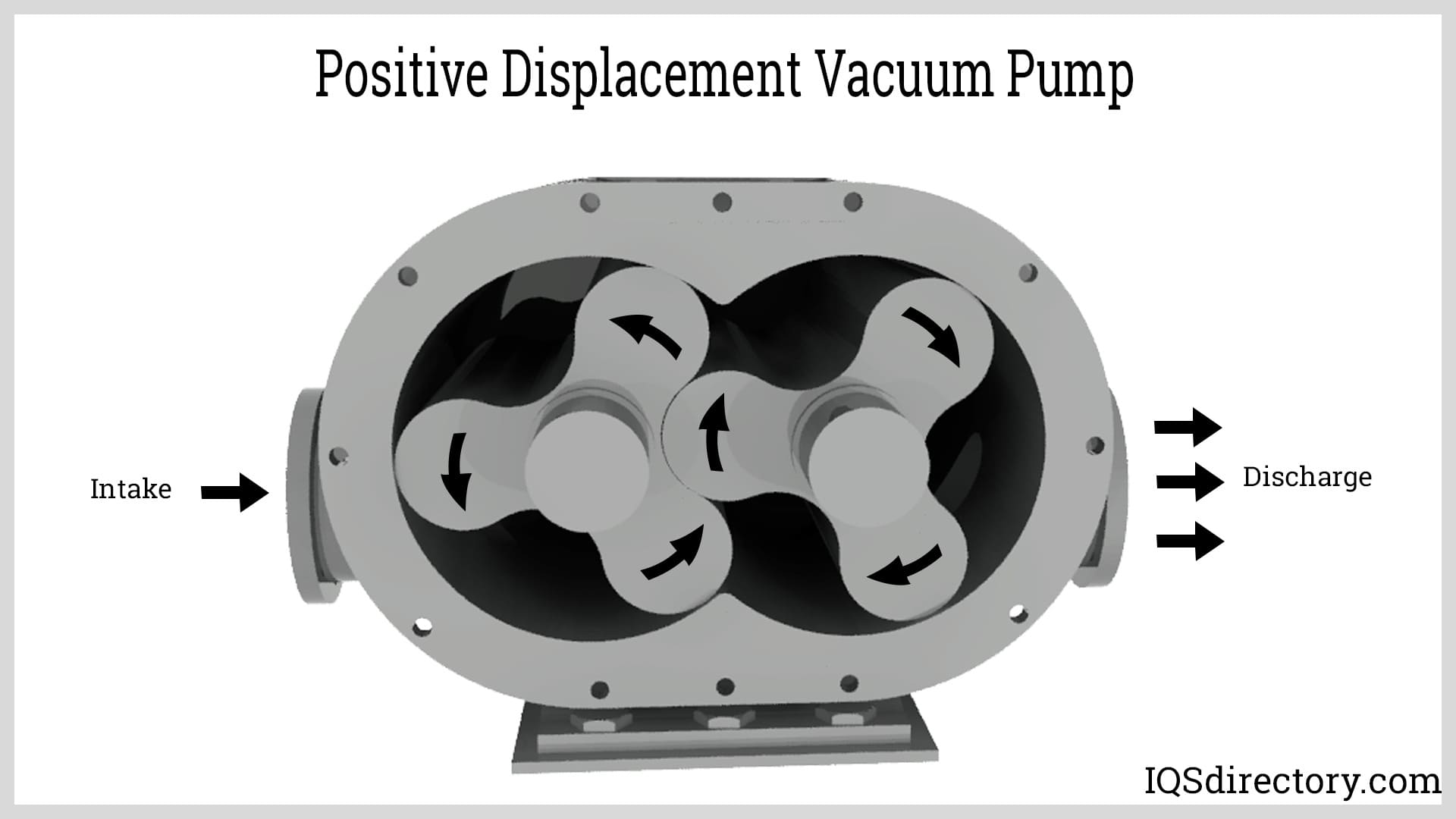

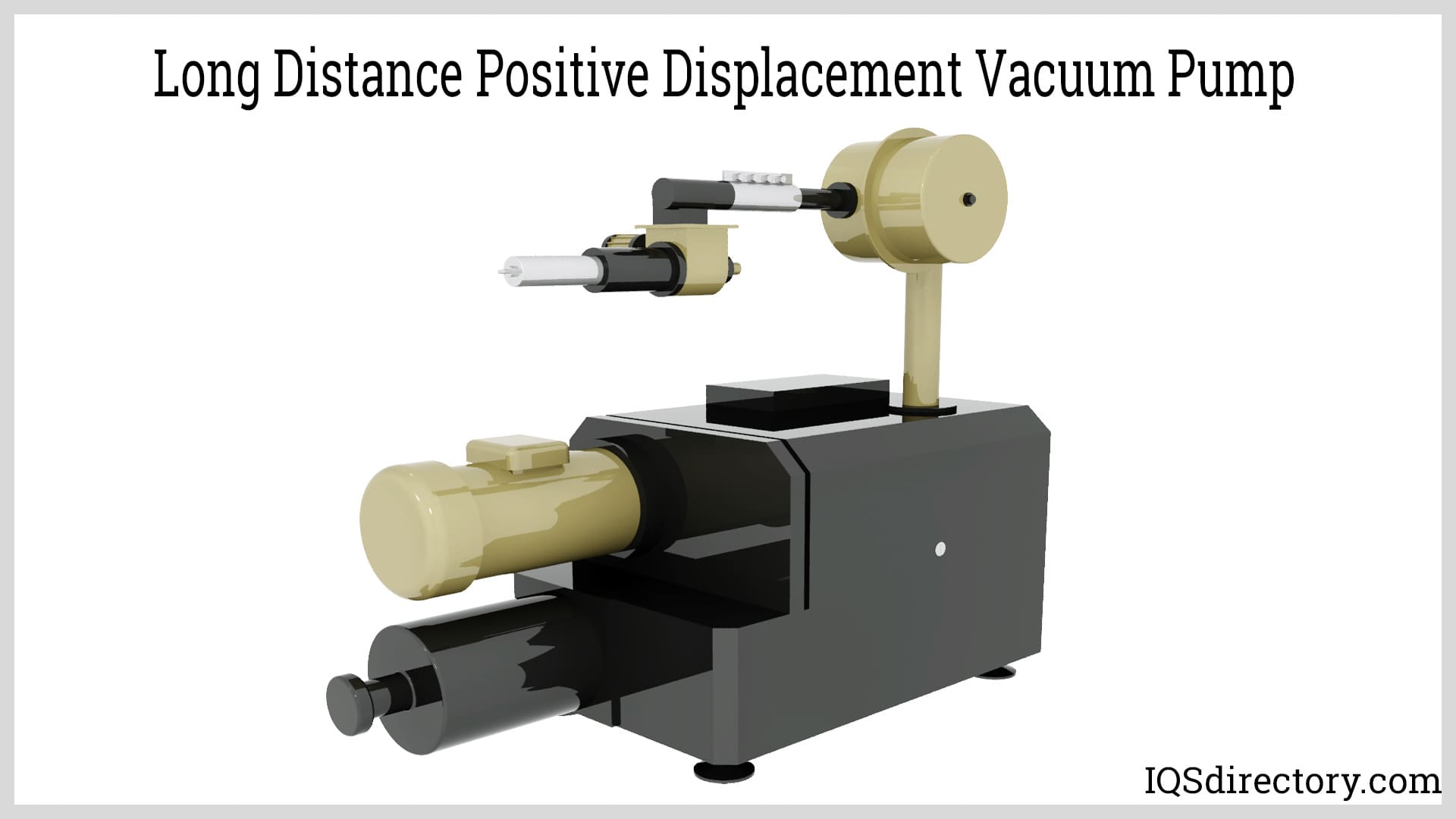

The three pumps used to power a vacuum conveying system are regenerative, positive displacement, and long-distance displacement. They vary by their efficiency, length of system, line sizes, style of impeller, vacuum level, and throughput. The power and capabilities of each type are chosen according to the type of material being transported since there is a great deal of difference between transporting powder and granular materials.

- Regenerative Pump – Regenerative pumps are used for small conveying systems of less than 500 feet (152 m) with a line diameter of 2.5 in (63.5 mm). They are motor power driven with one or dual impellers. Regenerative pumps are known for their high pressure and low volume and their ability to increase air pressure for vacuum conveyor applications.

The frictionless direct mounting of regenerative vacuum pumps makes it possible for their impeller to spin faster by its own internal pressure differential. The success of regenerative pumps depends on their ability to pull large volumes of air to build up the vacuum to increase air velocity.

- Positive Displacement Vacuum Pumps – Positive displacement vacuum pumps have counter rotating lobe impellers for generating high levels of vacuum suction and airflow. The powerful rotating lobes make it possible for positive displacement vacuum pumps to move high volumes of materials over distances up to 1000 feet (304.8 m). They are belt driven by a three-phase motor. The principle behind positive displacement vacuum pumps is to create a vacuum by expanding the volume in the piping.

- Long Distance Positive (LDP) Displacement Vacuum Pumps – LDP pumps use counter rotating claw impellers that cut through, pressurizes, captures, and compresses air. Since they minimize draft and vibrations, LDP pumps operate quieter and are more energy efficient. The increase in the level of the vacuum in LDP pumps makes the system able to suspend, support, and carry a higher volume of material in the line over longer distances.

Unlike typical vacuum systems that operate at a differential pressure of 10 or 11 Hg, LDP pumps run at 12 to 16 Hg or a little more. This difference enables a LDP system to move material over greater distances. With a variable frequency drive (VFD), the performance of a LDP pump can be controlled to match the line size and the speed of the material.

Feed Station

The feed station is for product intake and can be a silo, big bag station, barrel, or an assorted type of container. It is linked directly to the piping or transport line and supplies the piping with the product to be transported. The feed station supplies additional air under the influence of the vacuum in the piping, which creates a material and air mixture.

A vacuum feed station can be loaded using a vacuum lid through which the material to be loaded is filtered and drawn into the hopper or feed station. A discharge valve, located at the bottom of the hopper or feed station, is closed during the loading phase. When the feed station is fully loaded, the loading vacuum is turned off and the discharge valve is opened. Once the feed station is empty, the load cycle begins and the discharge valve is closed.

Piping Network

Conveying pipes are the transport system for a vacuum conveyor. Air flow created by the vacuum pump moves the material through the conveying piping. Although it may be assumed that the material moves vertically through the piping, bends, curves, and angles in the piping system reduce the distance that the system can move materials. Additionally, running into bends and curves may damage the material being transported, which further determines the length of the piping.

The materials used to manufacture the piping vary but must be capable of withstanding the internal and external pressures from the system. Careful consideration is given to the selection of pipe elbows and connectors, which are normally made of stainless steel or aluminum. The velocity of the transport requires that the piping be smooth and the inner surface be reinforced.

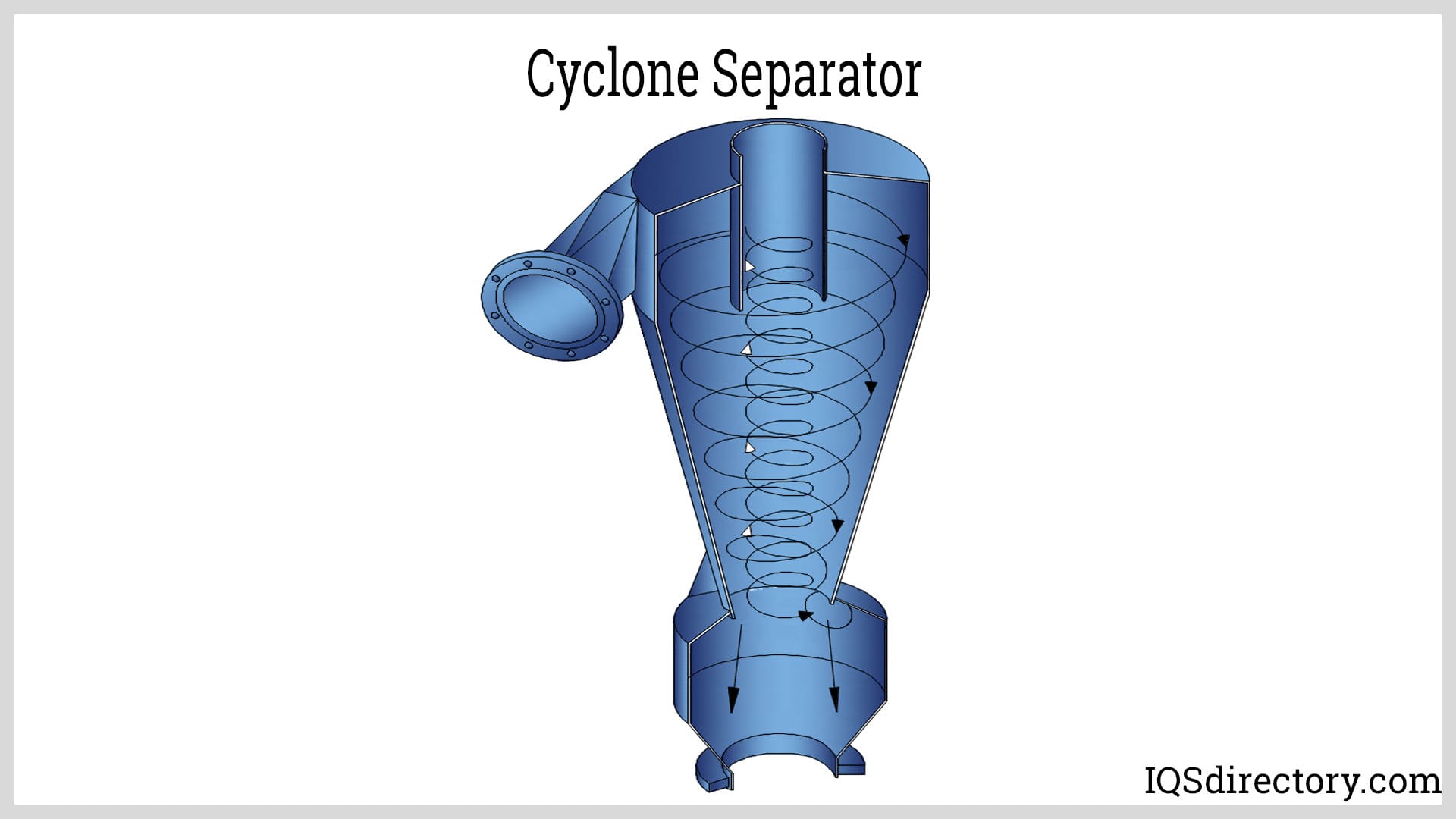

Cyclone Separator

Once the material being transported by a vacuum conveyor reaches its destination, it has to be separated from the air stream and deposited in a receiving container. Cyclone separators do not require moving parts or filters to perform the separation process. They have a simple design and use centrifugal force to separate the conveyor air from the solid particles being transported. The rotation of the separator moves the heavier particles to the walls of the separator and allows the air or gas to pass through. Cyclone separators can remove particles that range from micrometers up to several millimeters.

Control System

All vacuum conveyors necessitate the use of a control system, which is designed to control the many aspects of the process. The design and configuration of the control system is determined by the many factors related to the vacuum conveying process. It is essential that it meets the needs of the application, the application environment, and the requirements of the materials being transported.

Control systems can have any number of configurations including being fully pneumatic, fully electric, or a combination of several factors. As the conveying system becomes more complex, slave units may be used to receive signals in order to manage the system. Computer control systems make it possible to oversee each phase of the vacuum conveying process and make adjustments as needed.

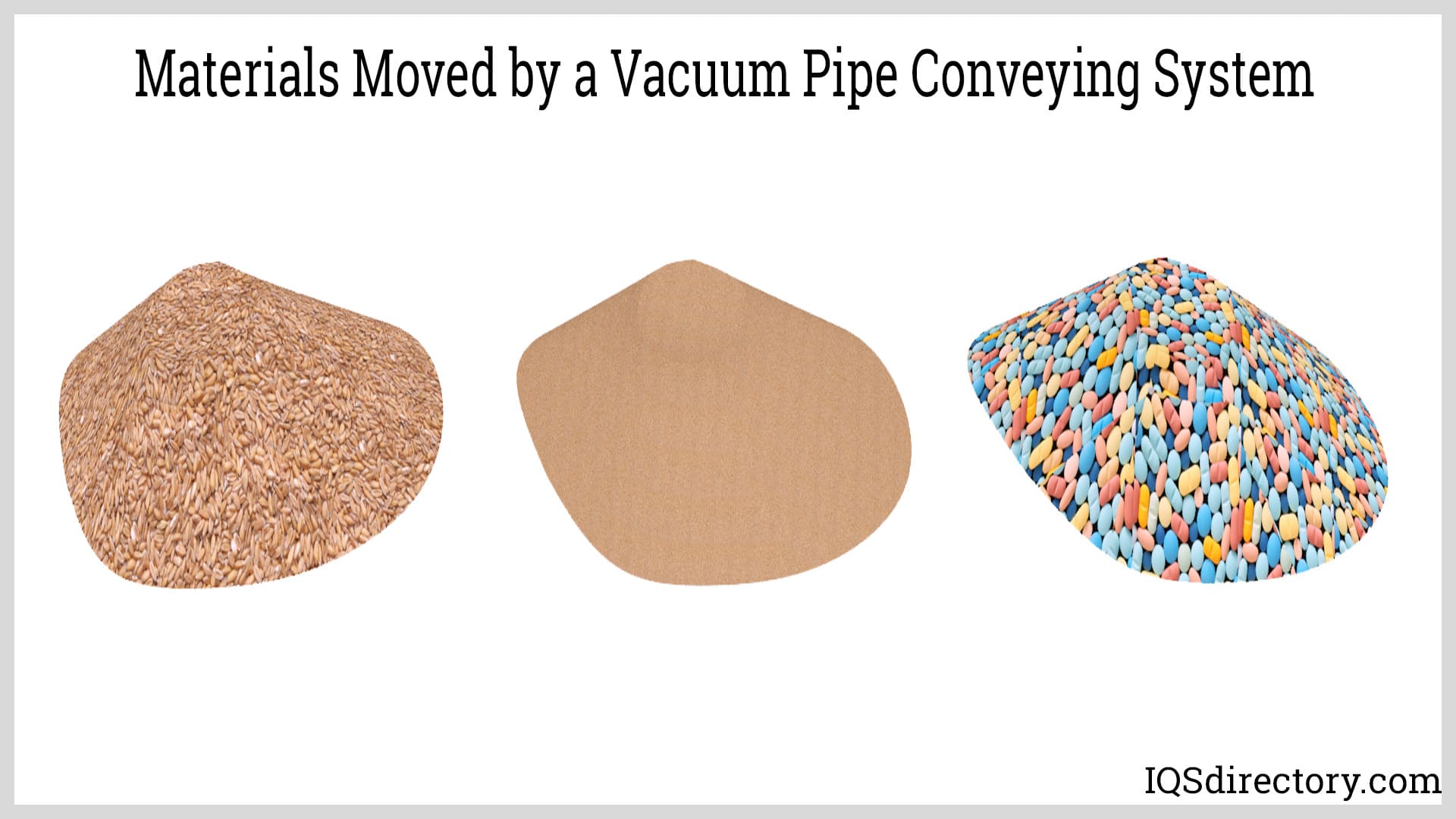

Materials Transported by Vacuum Pipe Conveyor Systems

There is a wide range of materials that are transported by a vacuum pipe conveying system. The range of materials includes the finest powders and granular materials to high density plastic resins and pharmaceuticals. Any industry that deals with particulate matter relies on vacuum conveying to supply production lies and other operational processes.

Materials that can be transported by a vacuum pipe conveying system include:

- Powdery Materials – lime and paint pigments

- Granular Materials – grains, coffee beans, and sand

- Coarse Grained Materials – gravel, screws, and metal parts

- Small Food Items – cucumbers, diced ham, and steaks

Components of a Vacuum Belt Conveying System

Vacuum belt conveyors are used to securely hold lightweight products, ones with a large area, or flat thin sheets. They have the same basic structure as all other forms of belt conveyors with the exception of the supporting plate, conveying belt, and suction pump, each of which are unique to vacuum conveyor belts.

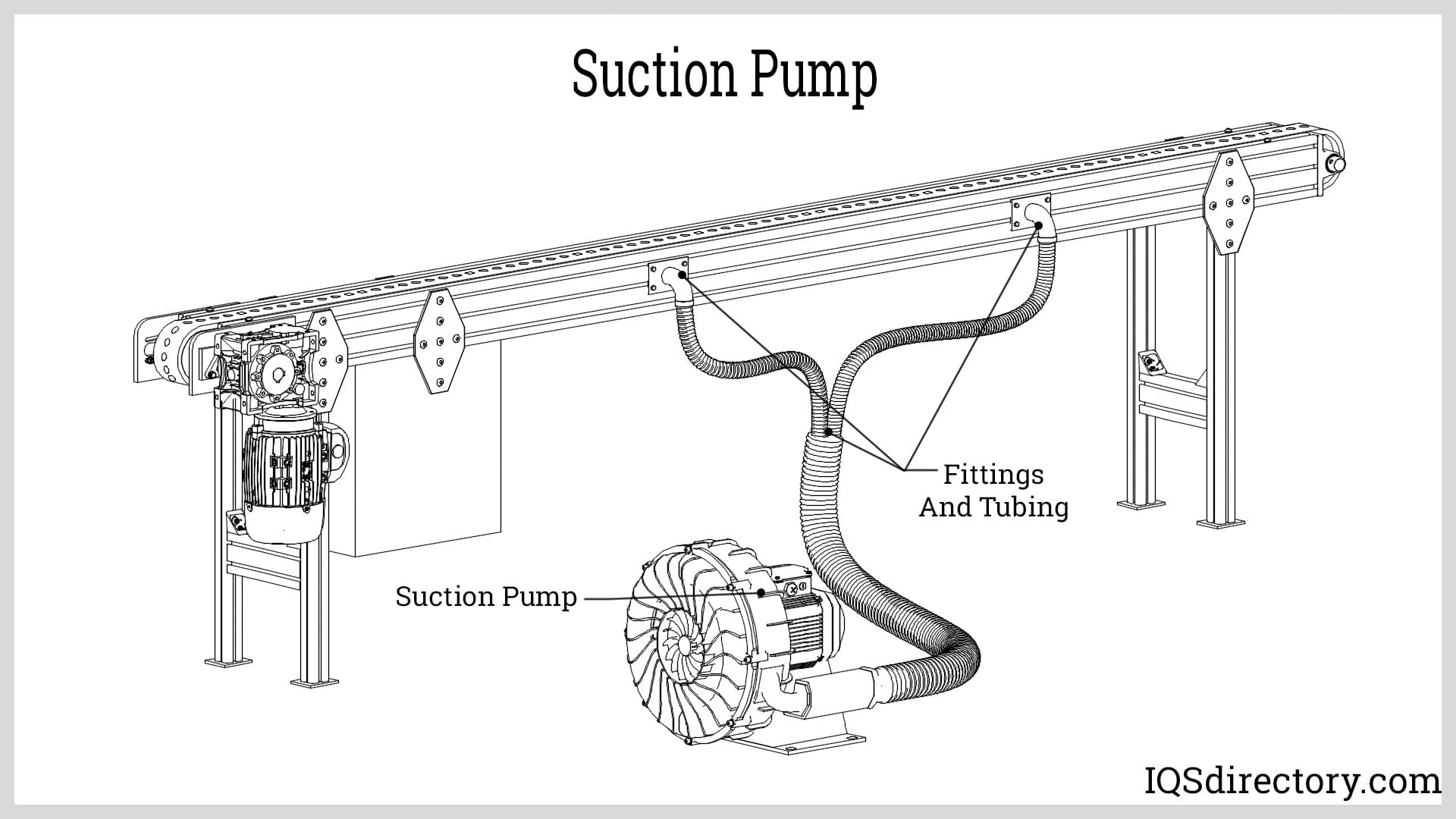

Suction Pump

The suction pump is an essential part of vacuum belt conveyors. It creates the suction power to pull the air flow through the perforated belt and conveyor plate to keep items flat on the belt. The frame of the conveyor has suction fittings to which suction lines are attached to create a vacuum inside the conveyor frame. The placement of the fittings allows for maximum flow rate to establish the vacuum.

The suction process of the suction pump is able to create positive and negative pressure under the perforated belt. The positive pressure reacts on the underside of the belt where there are no holes and acts like an air bearing to reduce belt drag. The negative pressure acts on the materials on the belt that are being conveyed and holds them securely in place.

Bed Plate

The bed plate for vacuum belt conveyors is custom designed with a vacuum chamber to focus the suction from the pump. A random number of holes are drilled into the bed plate that are positioned according to the requirements of the product and application. It provides the connection between the belt and the vacuum chamber.

Belts

The belt of a vacuum conveyor is the transport mechanism and comes in an endless number of sizes, shapes, and configurations. It is connected to the vacuum chamber and suction pump by the perforated plate upon which it rests. The fabric for belts for vacuum conveyor belts is essentially the same as those used for traditional conveyor belts with the key difference being the holes.

Unlike other industrial equipment, vacuum belt conveyors do not have a standard or common form of belt since the majority of vacuum belt conveyors are specially designed to fit a specific application. The weight, nature, structure, and configuration of the items transported on a vacuum belt conveyor determines the type of conveying belt. The key factor in the designing of the process is the security of the items being transported, which is the main reason for the use of a vacuum belt conveyor.

Vacuum belt conveyor belts can be a few inches wide or a couple of feet wide but are all attached to the drive mechanism at the end of the belt. The holes in the belt provide openings for the suction mechanism. The positive pressure produced by the suction pump reduces the little friction that the belt could experience.

Materials Transported by Vacuum Belt Conveyors

Vacuum belt conveyors are primarily used to transport small, lightweight, flat, and delicate materials that require special handling. They provide users with a certain level of security and are a positive alternative to traditional conveyors. The wide variety of configurations is due to the need to custom fit vacuum belt conveyors to the requirements of the products they transport.

The Benefit of Vacuum Conveying Systems

Vacuum conveying systems have been recognized for their efficiency, safety, convenience, and ease of operation. In many ways, they have revolutionized the processes of the supply chain and made it possible to rapidly manufacture and process various types of materials.

Conveyor Routing

Vacuum conveying systems can easily fit into any manufacturing environment. They can be routed horizontally and vertically through holes, across the ceiling, and over various operations. They easily integrate into any environment, regardless of the obstacles or types of equipment.

Products Handled

Any type of powder or granular material that has a bulk density can be transported by a vacuum conveying system. Flakes, pellets, resins, capsules, tablets, and friable, crumbled, or pulverized material can safely be placed in the system and easily moved.

Evacuation

One of the concerns when moving bulk materials is the amount of waste that is left behind in the feed container. Vacuum conveying systems ensure that every portion of the bulk material is removed and sent into the system. This complete transfer and evacuation ensures that individual and batch ingredients are transported to where they are needed with accurate weight, highest quality, and very limited waste.

Capacity

The versatility of the different configurations of vacuum conveying systems makes it possible to choose a system that perfectly fits the capacity range of an application. Vacuum conveying systems are able to move a few pounds up to several tons of material per hour, easily, efficiently, and rapidly. Feeds can be for small packaging operations or high-capacity railway cars and silos, regardless of changes in the feed rate.

Enclosed System

As anyone in any aspect of bulk transport can tell you, contamination of transported materials is a constant concern, especially when performed in the open. Vacuum conveying systems are completely enclosed and sealed, which serves as prevention and protection from contamination of products, ingredients, food stuffs, or plastic resins. It is a safe, secure, and contamination free conveying process that does not expose materials to the outer atmosphere.

Reliability

One of the main reasons for the popularity of vacuum conveying systems is their reliability, which is unlike the many other conveyance systems. Vacuum conveying systems have access doors, inspection ports, filter receivers, control systems, and air lock valves that make it easy to access the system and prevent any obstructions to the system’s performance.

Sanitary

Many of the products that are moved by vacuum conveying systems are sensitive and require special treatment. They have a set of standards that must be followed to ensure that they can be used without fear of contamination. Vacuum conveying systems, with their tight seal and closed conveyance, have the highest standards of hygiene and cleanliness. The food and pharmaceutical industries rely on the contaminate free aspects of vacuum conveying to ensure the safety of their products.

Benefits of Vacuum Belt Conveyors

The function of vacuum belt conveyors is the handling of delicate and sensitive materials that must be held securely in place during transport. The selection of a vacuum belt conveyor is based on certain factors that ensure the quality of products and safe material movement.

Fixed Positioning

A vacuum belt conveyor makes it possible to position an item on the conveyor belt without the need of grippers, pallets, or cleats. The suction mechanism ensures that an item remains set in place without concern for it shifting or falling.

Security

Over the years, it has been difficult to find a conveying system capable of transporting light sheets of plastic, delicate and sensitive equipment, or other fragile items. Traditional conveyors can have cleats or product holders to transport fragile products but cause them to shift and move during transport. The introduction of vacuum conveyor belts enhanced conveying systems that make it possible to convey fragile items without the need for extra handling.

Orientation

Although there are conveying systems capable of moving products in several orientations, vacuum conveyor belts are able to move products horizontally and overhead using the force of suction to hold them in place.

Quality Checks

A factor that makes vacuum conveyor belts so perfect is their ability to make it possible to check the quality of a product while it is moving down the conveyor line. Optical comparators can examine and identify products, regardless of how fragile or delicate they are, as they move along the system.

How to Select a Vacuum Conveying System

Regardless of the wide use of vacuum conveying systems, there are few systems that easily fit into every application. The many facets of vacuum conveying systems necessitate careful consideration regarding the system to be used. The essential and most practical aspects of the selection process is the types of bulk materials that will be moved.

Bulk Materials

It is important to understand that not all vacuum conveying systems are capable of handling all bulk materials. The consistency of the material being transported affects the quality of the final product. Things to be considered about bulk materials when selecting a vacuum conveying system are density, particle size, particle properties, and how the environment affects the material.

The bulk density of a product is measured in pounds or grams per cubic foot or cubic centimeter and are the key factors for the conveyor line and vacuum pump. Prior to investing in a vacuum conveying system, it is advised to test the material to be transported in the system to determine how the system changes the density of the product.

Distance

The distance and flow rate of a product is determined by the density of the product. The pipe diameter, length of the pipe, number of inlets and outlets, and type of conveying mechanism are guiding factors when choosing a vacuum conveying system. Providing a vacuum conveyor supplier with the proper statistical data can assist in the proper selection of the appropriate system.

Specifications of the System

As indicated, a vacuum conveying system is a complex and intricate set of tools that are designed to efficiently move bulk materials and products. During the selection process, every aspect of the system needs to be stipulated from the upstream hopper, reactor, and feeder to the filters and vents in the system. Additionally, the shape the material will take during transport needs to be determined, which can be batches or continuous feed. These characteristics are factors in the selection process that a vacuum conveyor supplier will identify and examine in order to make the best selection.

Environment

As every manufacturer can explain, where a product is handled is just as consequential as the mechanism used to handle it. Temperature and moisture are environmental conditions that can drastically influence the performance of a vacuum conveying system. These factors relate directly to the type of material being transported and its consistency.

Regardless of the general factors relating to the selection of a vacuum conveying system, every system will require careful examination and consideration prior to installation. In essence, the installation of a vacuum conveying system can be less stressful than the selection process due to the fact that when the installation stage is reached, all other factors have been negotiated and corrected.

Conclusion

- A vacuum conveyor is a product movement system that relies on the use of suction to create a vacuum for material movement. The forms of vacuum conveyors vary from belt types of conveyors that use suction to keep products on a belt to tube or pipe vacuum conveyors that use a system of pipes

- Vacuum conveying using a pipe system uses negative pressure to move powders and bulk solids to the next step in production, different locations, unload trucks, or for further processing.

- Vacuum belt conveyors work like all forms of belt conveyors but have a perforated surface connected to a vacuum system that causes suction between items on the belt and the belt.

- The tube and belt vacuum conveyors are further divided into different types that are defined by their method for producing a vacuum, the types of materials they move, and the materials from which they are made. The different types of vacuum conveyors are designed to perform specific tasks with the majority of vacuum conveyors being custom designed and configured.

- The concept of vacuum pipe conveying is built on the principle of negative pressure and air velocity to transport large quantities of powders and granular products. The key element of a vacuum pipe conveying system is its blower pump that creates the negative pressure to pull product through the system.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services