Whirl-Air-Flow Corporation

Whirl-Air-Flow CorporationRequest A Quote

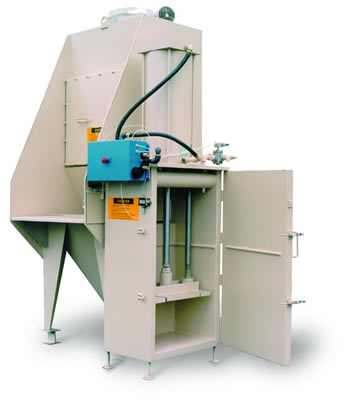

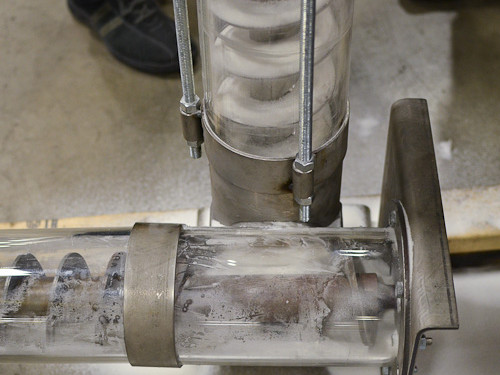

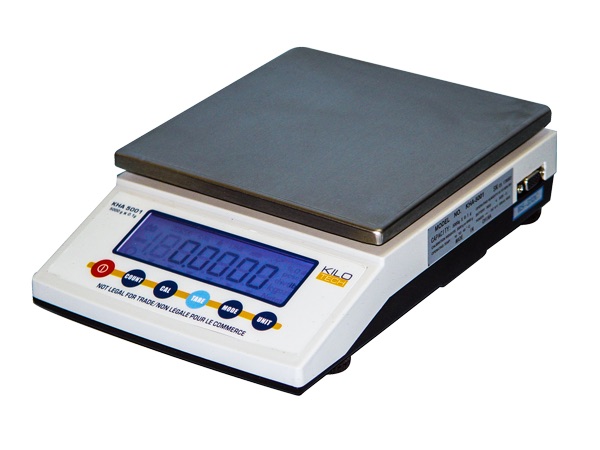

Princeton ,MN | 763-262-1200Whirl-Air-Flow has been specializing in the design, development and fabrication of pneumatic conveying systems since 1946. Our vast experience in dense and dilute phase conveying systems spans across a broad range of industries. Whirl-Air-Flow has over 55 years of specializing in dense and dilute phase conveying systems, blending systems, bag unloading systems, central vacuum systems, process controls and air slides to name a few. We provide in-house specialty fabrication in an ASME Certified fabrication facility of code vessels, specialty tanks, support structures, and periphery equipment. Our unique design uses dense phase pneumatic conveying to deliver the blended batch without segregation to one or more process areas. Our product can easily be mounted on a load cell weighing system and allows fully automatic operation. Whirl-Air Batch Blenders/Transporters are perfect for a variety of applications such as, tile grout, pancake mix, dry cake mix, clay blends, plaster, tire pigments, pharmaceuticals and so much more. Whirl-Air’s in-house fabrication, assembly and machining capabilities are un-matched. By providing the manufacturing and fabrication services in-house, Whirl-Air ensures that your system is built to exact specifications, with major subassemblies assembled on our shop floor before shipment to ensure proper fit. We can provide our customers with complete mechanical and electrical engineering, full fabrication of carbon steel, stainless and aluminum. With Whirl-Air, our customers are getting a high-quality product they can rely on. We provide field technicians to oversee your project through installation, start-up and run-in. Due to our extensive network and direct factory support, Whirl-Air’s systems are provided worldwide. For more information on how we can help you, visit our website or give us a call today!

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services