Conveyor systems are common in various industries because they offer a cheap and efficient way to handle bulk materials while minimizing material loss. There are numerous types of conveying systems that can be utilized depending on the requirements of the specific business. Particles ranging in size from tiny granules to pellets can be handled pneumatically, making them useful for use in the construction and technology industries. Read More…

VAC-U-MAX is a premier custom pneumatic conveyors manufacturer of support equipment for conveying, batching and weighing materials. With our system your company’s product can move gently and quickly from point to point, with nothing in the way to impede the efficiency of its movement. Contact VAC-U-MAX today so they can find the perfect product for you.

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry.

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

At ENTEK, we are a dynamic team of experts specializing in pneumatic conveyors, dedicated to providing innovative solutions that streamline material handling processes for a wide range of industries. With a proven track record of excellence and a commitment to customer satisfaction, we have established ourselves as a trusted partner for clients seeking efficient and reliable conveying solutions....

More Pneumatic Conveying System Manufacturers

Design of Pneumatic Conveying Systems

Mathematical models, test data, or a combination of both may be used to design a pneumatic conveying system. If mathematical models are to be used, some level of assurance regarding their fitness for a certain purpose, such as transmitting a specific material under precisely defined conditions, must be established before they are used. System design makes heavy use of test results. This information may have come from a testing facility or from sharing experience from a real plant.

However, it is crucial that the data pertain to the same grade of material that the new plant design is needed for. The data must also be supplied for a conveying line’s marginally lower level of intake air velocity and a marginally higher level of solids loading ratio than those considered for the new design. Existing data should never be scaled beyond limitations of known transmitting.

Structure and Functionality of Pneumatic Conveying Systems

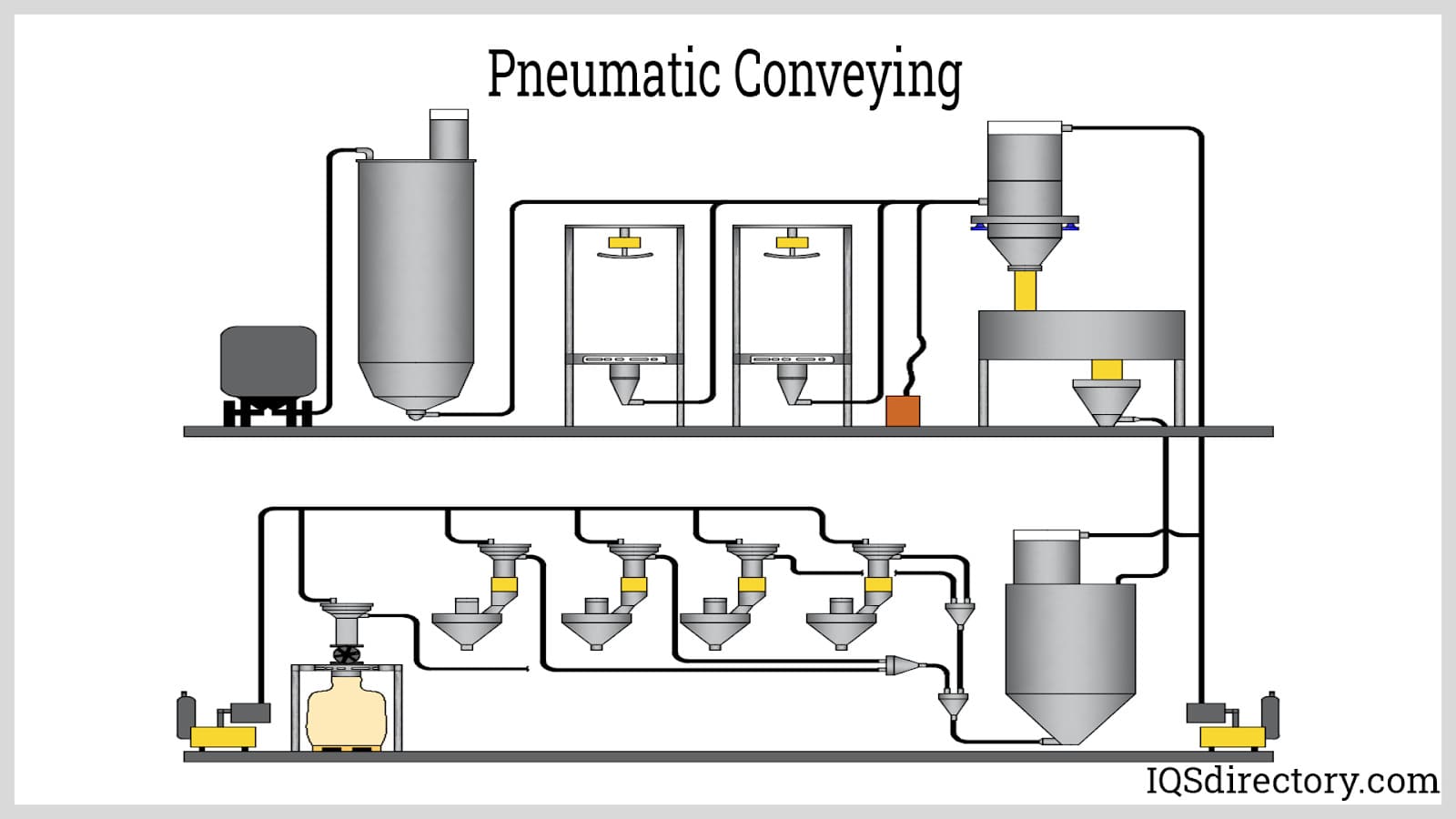

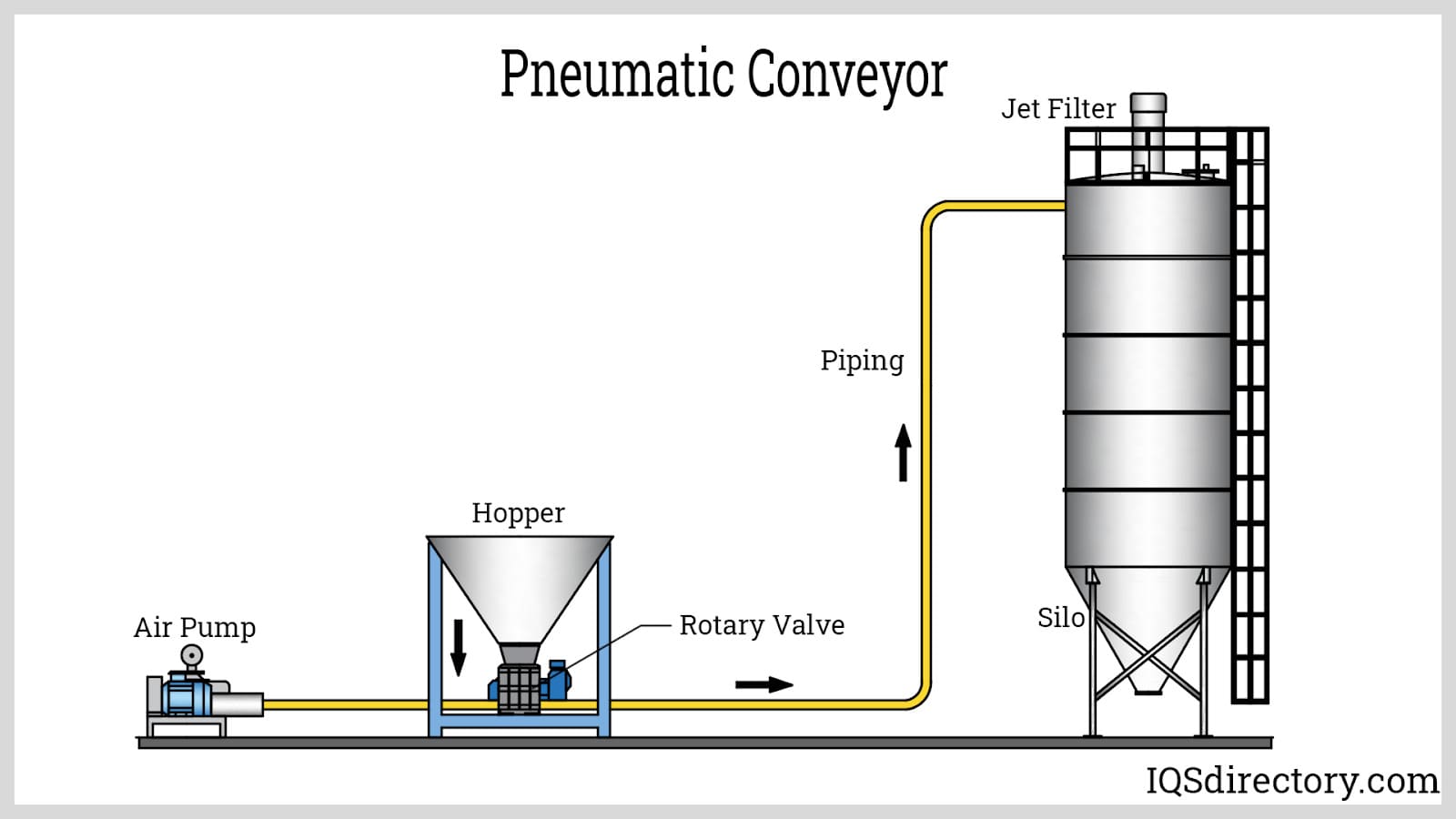

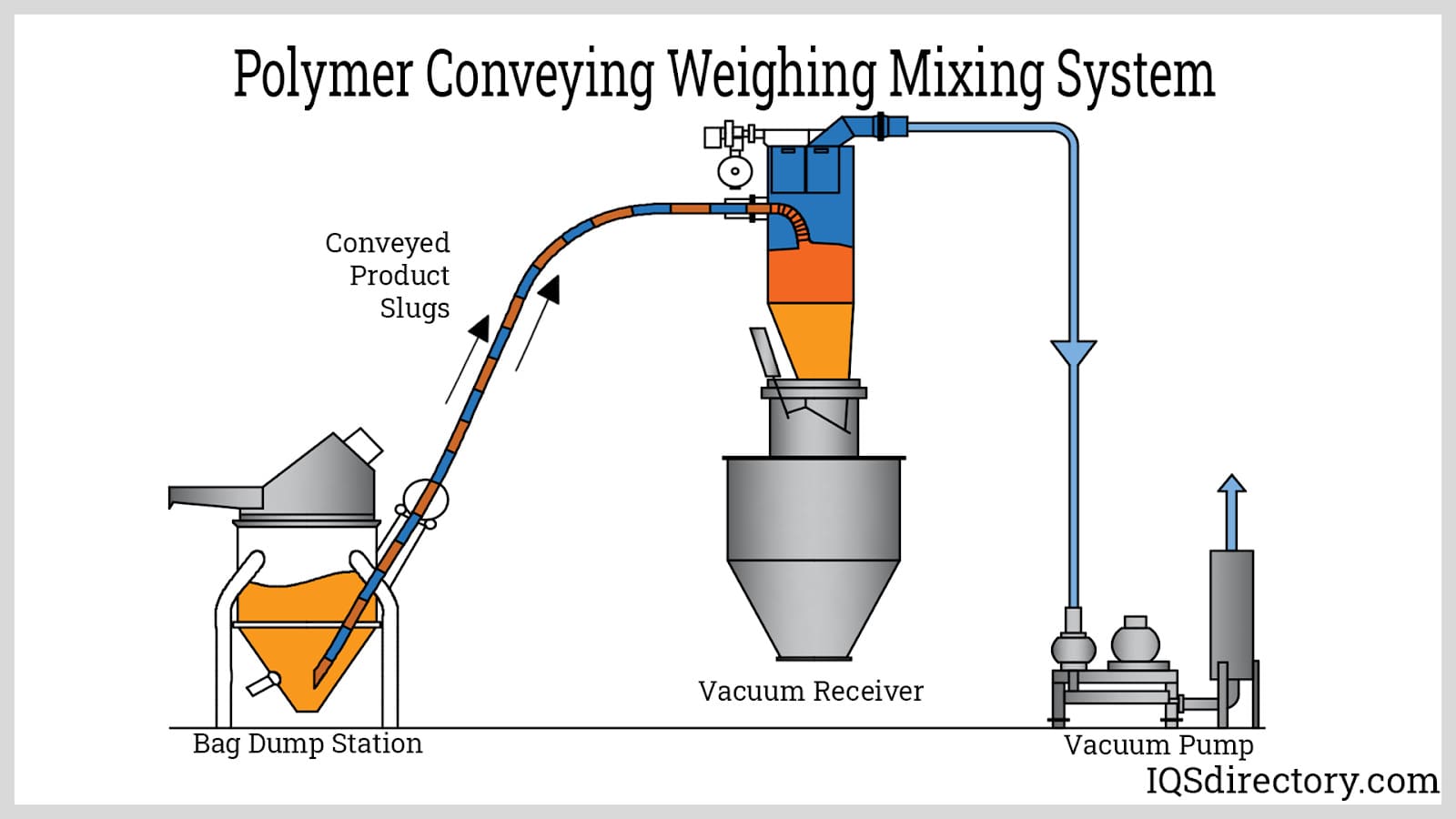

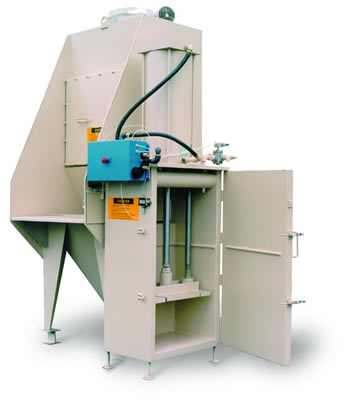

The bulk materials are moved via pneumatic conveying equipment and a pipeline. A material insertion point, pipes, receiving point, and an air-flow movement device are common system components; nevertheless, the precise nature and capacity of a system vary from model to model.

Pneumatic conveying system pipes are adaptable and may be routed around machinery, allowing them to be installed in existing locations. A practical, affordable method of moving products from point A to point B, well-designed pneumatic conveying systems are more efficient than competing mechanical systems.

A pneumatic system is an industrial conveyor system that can travel large distances vertically or horizontally and provides protection from dust emissions into the air. Comparatively speaking, mechanical conveying systems, maintenance, equipment, and operating costs are decreased.

Pneumatic Conveying Methods

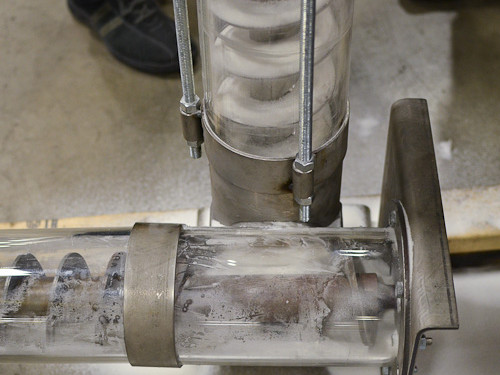

The materials are moved using air streams, either vacuum or pressure, and there are three main types of pneumatic conveyor methods: dense phase, dilute phase, and air conveying. These methods operate in relation to, and in accordance with, the specific velocities, pressures, and air to commodity ratios within the system.

Continuous, high velocity, low pressure, and high air-to commodity-loading ratio processes are used in dilute phase conveying. Pulling or pushing material through an airstream at a certain speed helps the process. Positive pressure, vacuum (negative pressure), or a combination of the two can be used to build the system.

Pneumatic conveying systems operate without exposing the materials being moved to moving parts because they are enclosed. Pressure systems input compressed air at the insertion or system inlet to force materials through, while pneumatic vacuum systems administer a vacuum at the receiving end to pull the material through the enclosed pipes.

Considerations When Choosing Pneumatic Conveying Systems

The considerations include:

- Particle size shape and distribution

- Air humidity

- Moisture content

- Concentration

- System throughput

- System distance

- Angles of flow, repose, and slip

- Density

- Fluidization

- Hardness / Friability

- Temperature

Areas of Application of Pneumatic Conveying Systems

Services provided by pneumatic conveying systems involve complete system engineering for systems applications like start-up service, full-scale material testing, spare parts and field service.They also convey difficult-to-handle material such as abrasive, attrition-sensitive or fragile products. Innovative feeder-control algorithms featuring second-to-second accurate performance can be applied even in aggressive plant environments. They also provide an extensive line of mechanisms for applications in the chemical, plastics, mineral, pet food, food and pharmaceutical process industries while offering solutions for applications in very high sanitary demands and according to government specifications and customers.

Advantages of Pneumatic Conveying Systems

The advantages are as follows:

- A pneumatic conveying system allows greater versatility than a mechanical conveying system because it may be compatible with existing equipment due to the small nature of the conveying pipe’s transfer line.

- These systems can cover a large distance running either horizontally or vertically.

- Due to the enclosure of the system, both the delivered material and dust emission to the atmosphere are protected from outside contaminants.

- Because they have fewer moving components than mechanical conveying systems, pneumatic conveying systems can be simpler and more cost-effective to maintain.

- They maintain a capacity to keep the environment around the substance under control.

- They reduce abrasive material wearing on the system and fragile materials damage.

- These systems are easier to find because they occupy less floor space.

- Various pick-up and discharge points are possible.

Choosing the Proper Pneumatic Conveying System Manufacturer

To make sure you have the most beneficial outcome when purchasing a pneumatic conveying system from a pneumatic conveying system manufacturer, it is important to compare at least 4 companies using our list of pneumatic conveying system manufacturers. Each pneumatic conveying system manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each pneumatic conveying system business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple pneumatic conveying system businesses with the same message.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

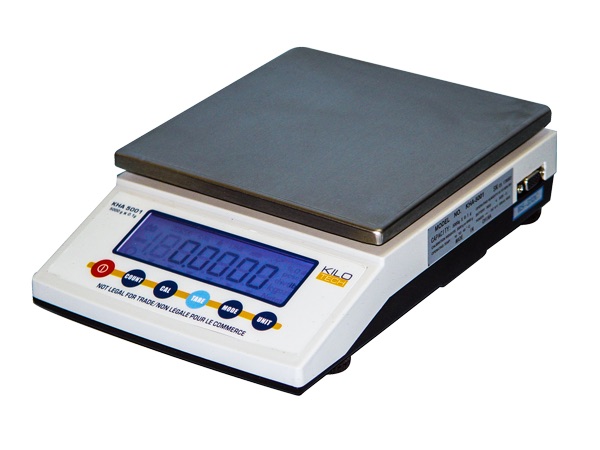

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services