Pneumatic conveying is an effective way of handling and moving different types of bulk powdered and granular products with negligible loss and at a lower cost than other systems. These products usually consist of granules or powders. These systems move materials via enclosed, airtight pipes by combining airflow, gas, and pressure. Read More…

VAC-U-MAX is a premier custom pneumatic conveyors manufacturer of support equipment for conveying, batching and weighing materials. With our system your company’s product can move gently and quickly from point to point, with nothing in the way to impede the efficiency of its movement. Contact VAC-U-MAX today so they can find the perfect product for you.

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry.

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

At ENTEK, we are a dynamic team of experts specializing in pneumatic conveyors, dedicated to providing innovative solutions that streamline material handling processes for a wide range of industries. With a proven track record of excellence and a commitment to customer satisfaction, we have established ourselves as a trusted partner for clients seeking efficient and reliable conveying solutions....

More Pneumatic Conveying Manufacturers

Operators can control negative or positive pressure of airflow to smoothly move products without worrying about loss or damage.

Working Principle of Pneumatic Conveying System

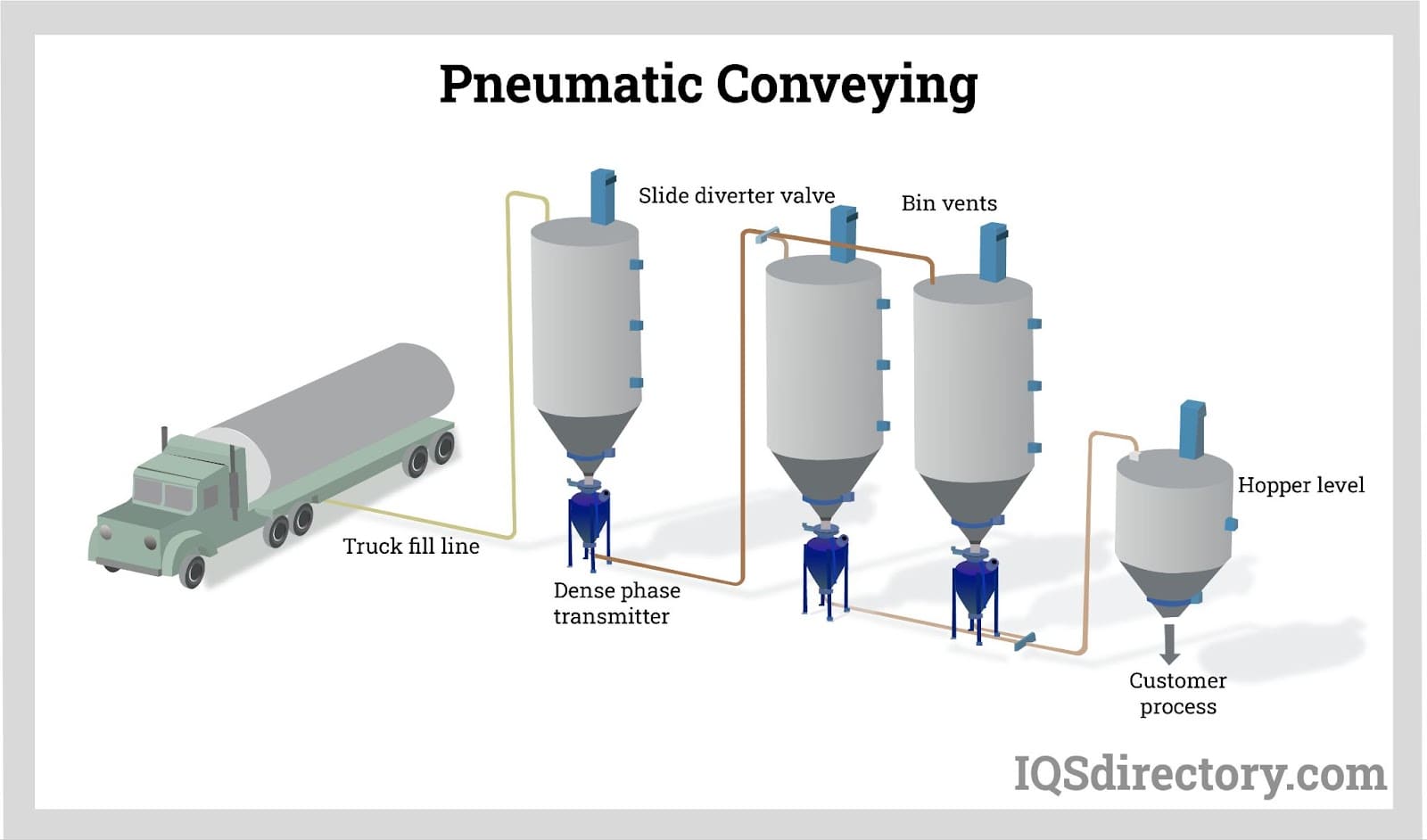

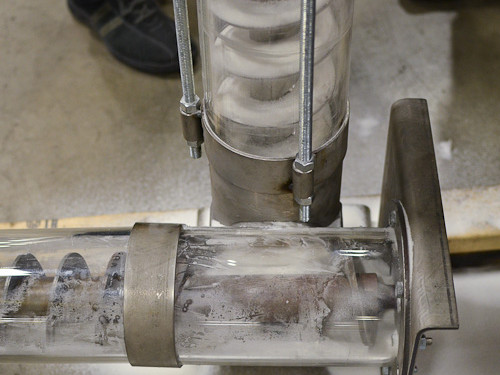

A pneumatic conveying system works by moving air through pipes, conveying a propulsion force that moves bulk products via the system from end to end. Pneumatic conveying requires a pressure difference between the system's start and endpoints. This is done through the usage of compressors, blowers, or fans.

The pressure difference relies on several influences, including the system's layout and length and the product's concentration and volume. The specific conveying method will differ between the different conveying system types, whether a dense or lean phase system.

Types of Pneumatic Conveying

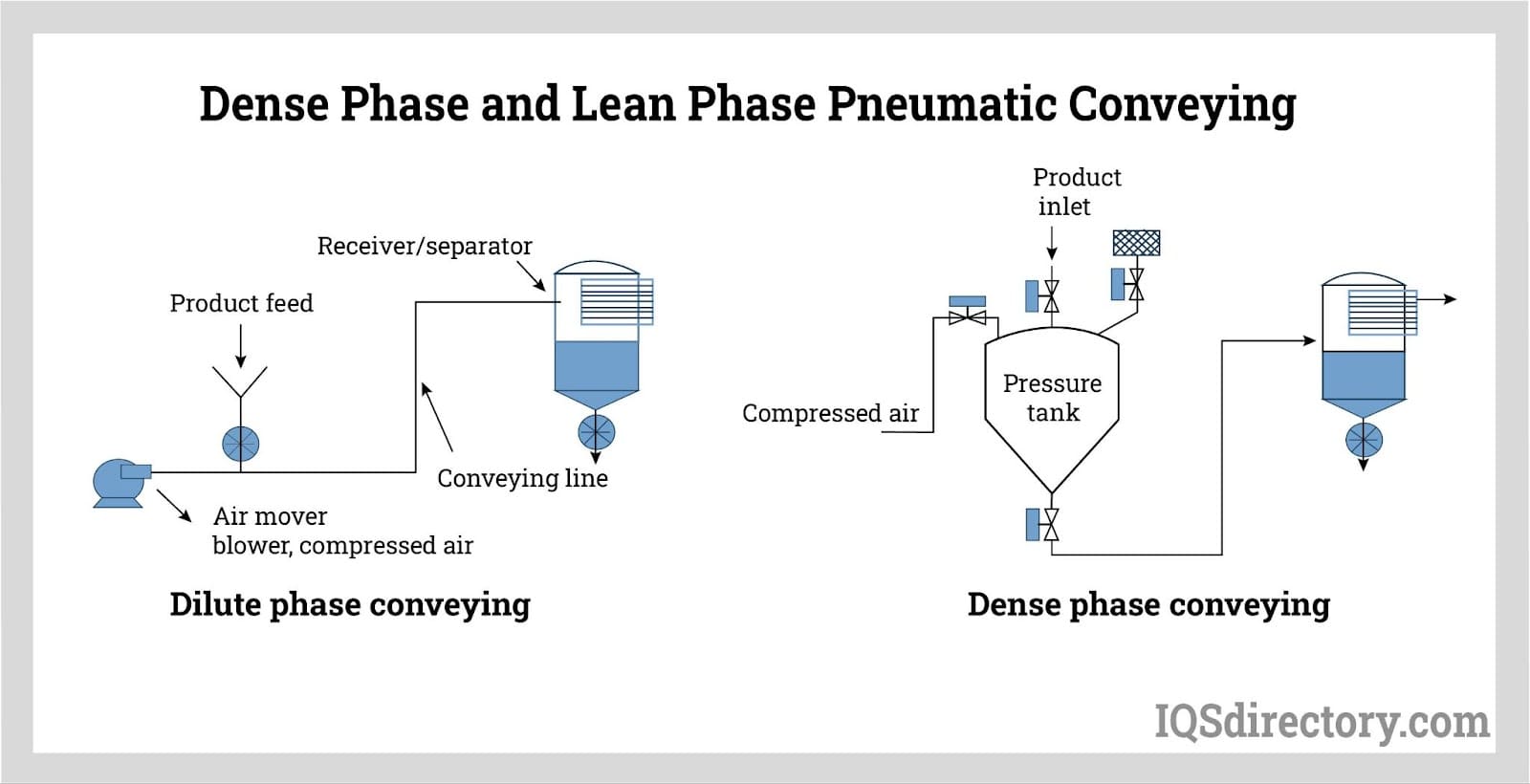

There are two primary pneumatic conveying types of systems to choose from: dense phase and lean phase. Each is applied in different uses and has different functions.

Lean Phase Pneumatic Conveying

This is the most commonly used pneumatic conveying system, a lean phase system for granules and powders. Two subdivisions stem from lean phase systems:

Dilute Phase Pneumatic Conveying

Dilute phase conveying systems use gas speeds greater than 17 to 18 m/s with vacuum or pressure below 0.1 bar. In a dilute phase conveying system, material granules/power is wholly suspended in the gas or air stream while the solid loading ratio is considerably lower.

This system is perfect for conveying smooth material with low bulk density. Most systems use fans or side channel blowers to transfer the products along the pipelines.

Medium Phase Pneumatic Conveying

In a medium-phase pneumatic conveying system, the air or gas velocity generally exceeds 17 to 18 m/s with a pressure or vacuum as high as 0.35 bar. Granules/Powder traveling through the pipes remain suspended, with a low concentration or solid loading ratio. Exhauster and root blowers are often applied to push air or gas via the system.

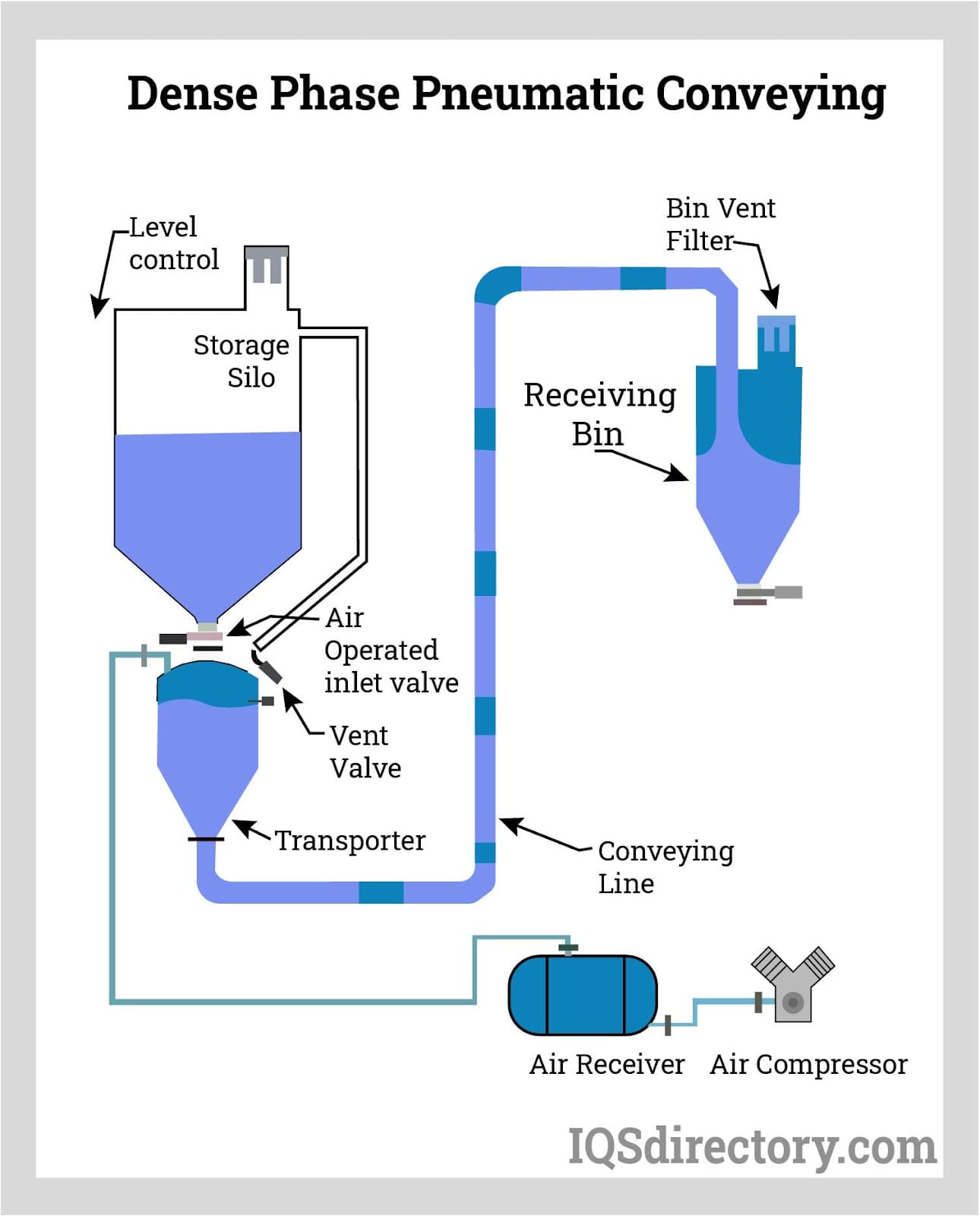

Dense Phase Pneumatic Conveying

A dense phase conveying system is perfect for moving fragile or sensitive products. These systems can transfer and handle products at low velocities, which helps avoid impact damage to the products. Dense phase systems use pulsations of air to push the products through, followed by another pulsation of both the product and air.

Unlike a lean phase system, a dense phase system needs a more precise calculation for design and proper timing. The overall density, dimensions of the granules/particles, and the route or length will help determine the air ratio to products when utilizing these systems.

Advantages of Pneumatic Conveying

There are several advantages of pneumatic conveying, like:

- Pneumatic conveyors can transport long distances either vertically or horizontally.

- These systems are simpler to locate because they need less floor space.

- The compact design of pipeline transfer lines makes it simple to route pneumatic conveyors around currently used equipment, making it fit in more applications than mechanical systems.

- Enclosed nature stops dust from entering the surrounding area and ensures that pollutants don't enter the pipeline.

- Operators can maintain a dependably controlled atmosphere.

- Multiple pickups and release points are available.

- Fewer moving parts imply that they're simpler to maintain when compared to mechanical systems.

Applications of Pneumatic Conveying

The applications of pneumatic conveying include:

Common Applications of Dilute Phase Systems:

- Smooth particles like flour

- Products which are difficult to break

- Light bulk density materials

Common Applications of Dense Phase Systems:

- Abrasives like sugar

- Materials with heavy-bulk density

- Blended products

- Particular friable materials such as carbon black pills

- Plastic pellets and more products that do not need continuous delivery

- Dense phase conveying

Based on the specifications of an application and the product type needed to transfer and handle, the proper pneumatic conveying system that gets the job done can be acquired.

Choosing the Pneumatic Conveying Company

To make sure you have the most positive outcome when selecting a pneumatic conveying company, it is important to compare at least 4 companies using our pneumatic conveying directory. Each pneumatic conveying company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each pneumatic conveying company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple pneumatic conveying companies with the same form.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

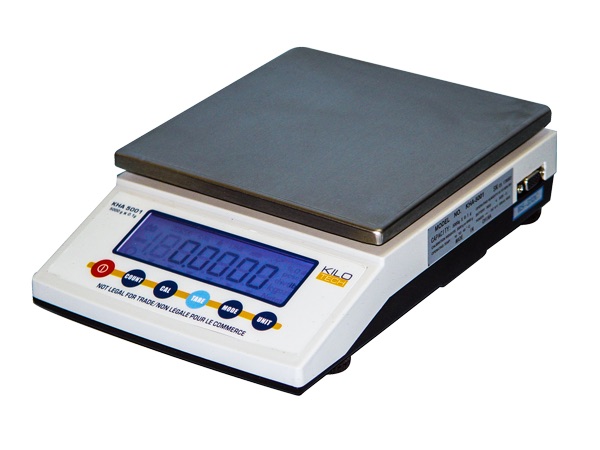

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services