Dense phase conveying is a process for shifting equipment across various light and heavy industries. It moves materials gently along the bottom of the pipeline using high pressure and small gas volumes as it passes from one silo to the next through enclosed pipelines. One of the two primary pneumatic techniques is dense phase conveying, often known as non-suspension flow. Read More…

VAC-U-MAX is a premier custom pneumatic conveyors manufacturer of support equipment for conveying, batching and weighing materials. With our system your company’s product can move gently and quickly from point to point, with nothing in the way to impede the efficiency of its movement. Contact VAC-U-MAX today so they can find the perfect product for you.

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry.

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

At ENTEK, we are a dynamic team of experts specializing in pneumatic conveyors, dedicated to providing innovative solutions that streamline material handling processes for a wide range of industries. With a proven track record of excellence and a commitment to customer satisfaction, we have established ourselves as a trusted partner for clients seeking efficient and reliable conveying solutions....

More Dense Phase Conveying Manufacturers

The other technique is known as dilute phase conveying. The primary distinctions between the two methods are pressure, the characteristics of the solids, and the rate of conveying speed. Transporting abrasive, brittle, or heavy materials like sand, soil, minerals, food, paper scraps, and boulders is specifically covered by dense phase conveying.

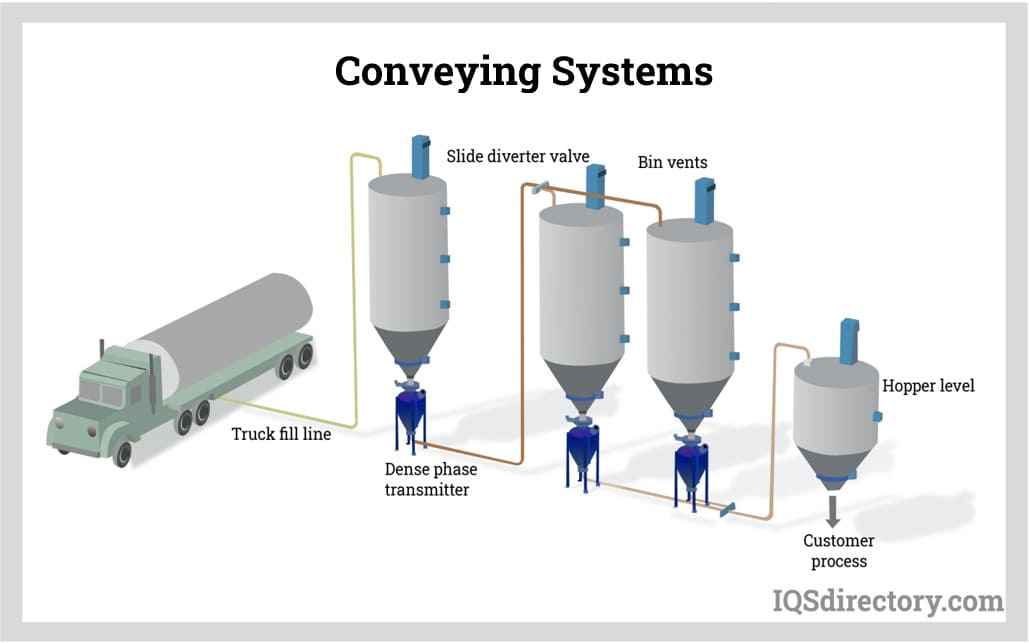

Principle of Operation

A pressure vessel is loaded from a silo, big-bag unloader, or process machinery, such as a mixer. The operation cycle entails loading the receiving hopper with material, applying pressure, and conveying the material as a plug or layer. With the "dense flow" PHF conveying system working at moderate gas velocities of 15–25 m/s, the solids can be transported as a continuous layer.

With the "pulse flow" PTA conveying system running at low gas velocities of 4–12 m/s, the solids can be transported as a pulsed plug. Finally, the solids can be carried as a pulsed plug using the "pulse line" PTA PL conveying system running at low gas velocities of 4–12 m/s with the addition of external air injectors installed along the pipeline for longer conveying distances and with maximum process safety.

Dense Phase Conveyor Design

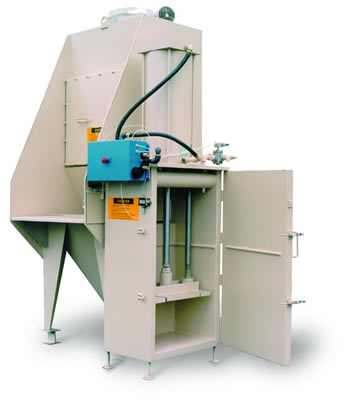

There are various designs for dense phase conveyors, which are enclosed tubular conveyors powered by air pressure and commonly loaded by gravity or vacuum while discharging goods from the bottom. Due to the materials conveyed being so densely concentrated, they will naturally deposit at the bottom, which is why the bottom-discharge design, in particular, lends itself to dense phase conveying so effectively. However, vacuum-loaded dense-phase conveyors pull products through utilizing a vacuum.

Moving-bed flow and plug flow are the two different types of flow used in dense phase conveying. Plug flow happens when the material is transported in units known as plugs or slugs that are separated by air spaces rather than one fluid body, as opposed to moving-bed flow, which occurs when the material is transported down the bottom of the conveyor pipeline.

System Design Elements

The physical qualities of the object being handled are the first of several system design factors to be considered. Factors considered include bulk density, abrasiveness, friability, particle size/distribution/shape, moisture content, temperature, and static charge. A pneumatic conveying system's rate, length, and pipeline routing arrangement will impact the overall system design. A dense phase system will typically have a smaller line diameter than a dilute phase system of a similar size. The smaller pipeline will require less installation area and money. This advantage is particularly notable when the line routing is lengthy and has numerous bends.

Air Injection Within the Conveying System

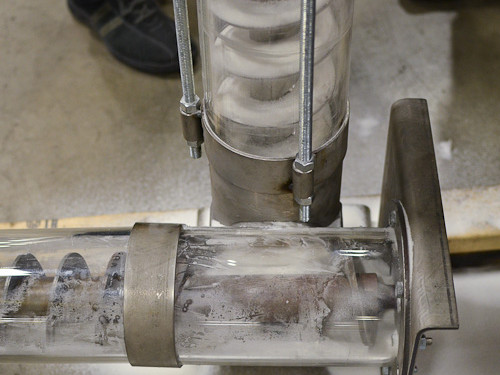

Another consideration is whether the conveying system needs to include more conveying line air injectors. Periodic air injection along the conveying line will improve the efficiency of some systems. In the fluidization examples mentioned above, strategically adding air pulses ensures that bulk materials move properly and with the least velocity throughout the pneumatic conveying system. Additionally, air injection can lessen fine particle bridging in the transporter's cone.

The powder can bridge above the transporter cone outlet and stop pouring into the line without transporter cone aeration. The powder in the transporter cone will get fluidized by strategically placed injectors, maintaining a steady flow into the line. A system that runs smoothly and doesn't plug depends on the air injection's position and pressure, whether in the transporter or along the conveying line.

Additionally, strategic air injection will decrease the system's overall gas consumption for greater efficiency. The reliability of the system is also considerably improved. The placements of the air injectors must be chosen to optimize material flow and make accurate estimations of the motive gas volume and conveying pressure.

Advantages of Dense Phase Conveying

Let's discuss the benefits of dense phase conveying. A low-velocity motive gas moves bulk materials in dense phase conveying, which can move both positive and negative pressure differentials. Low velocity produces a gentle transfer with less wear and impact on the materials. For most abrasive, brittle, friable, or mixed-batch materials, dense phase conveying is excellent. There is less product waste due to decreased product breakage. Additionally, material segregation is minimized, lowering the possibility of problems with subsequent processes.

Applications of Dense Phase Conveying

Dense-phase conveyors move materials with a low air-to-material ratio and a moderately low velocity. Frequently, dense-phase conveyors generate high-pressure levels with the use of an air compressor to move goods through the system at a typical rate of 275 feet per minute. Dilute phase conveyors are frequently used in the pharmaceutical, chemical, food processing, foundry, mining, plastics, and cement sectors.

In addition, dense phase conveying is frequently utilized in bulk material handling applications because it is perfect for transporting large amounts of materials. However, dilute phase conveying may also be used if the transported materials are light and non-abrasive.

Choosing the Correct Dense Phase Conveying Company

To ensure you have the most positive outcome when selecting a dense phase conveying company, it is important to compare several businesses using our directory of dense phase conveying companies. Each dense phase conveying company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each dense phase conveying company website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple dense phase conveying companies with the same form.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services