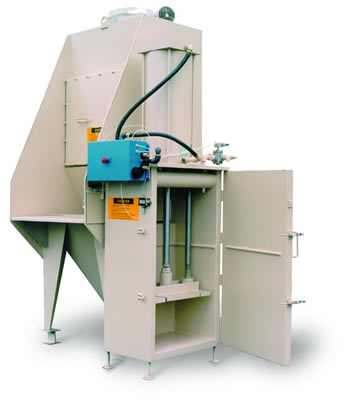

Bulk bag dischargers, or bulk bag unloaders, efficiently discharge powders or other dry bulk materials. A series of bags are employed to store or facilitate the transportation of otherwise challenging-to-store or transfer goods and commodities that would otherwise be difficult to handle. Bulk bag unloaders are particularly useful when the bags are considerably more challenging to unload manually, such as when materials have gotten tightly packed over time during storage. Read More…

VAC-U-MAX is a premier custom pneumatic conveyors manufacturer of support equipment for conveying, batching and weighing materials. With our system your company’s product can move gently and quickly from point to point, with nothing in the way to impede the efficiency of its movement. Contact VAC-U-MAX today so they can find the perfect product for you.

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry.

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

At ENTEK, we are a dynamic team of experts specializing in pneumatic conveyors, dedicated to providing innovative solutions that streamline material handling processes for a wide range of industries. With a proven track record of excellence and a commitment to customer satisfaction, we have established ourselves as a trusted partner for clients seeking efficient and reliable conveying solutions....

More Bulk Bag Unloader Manufacturers

Frame Configurations of Bulk Bag Unloaders

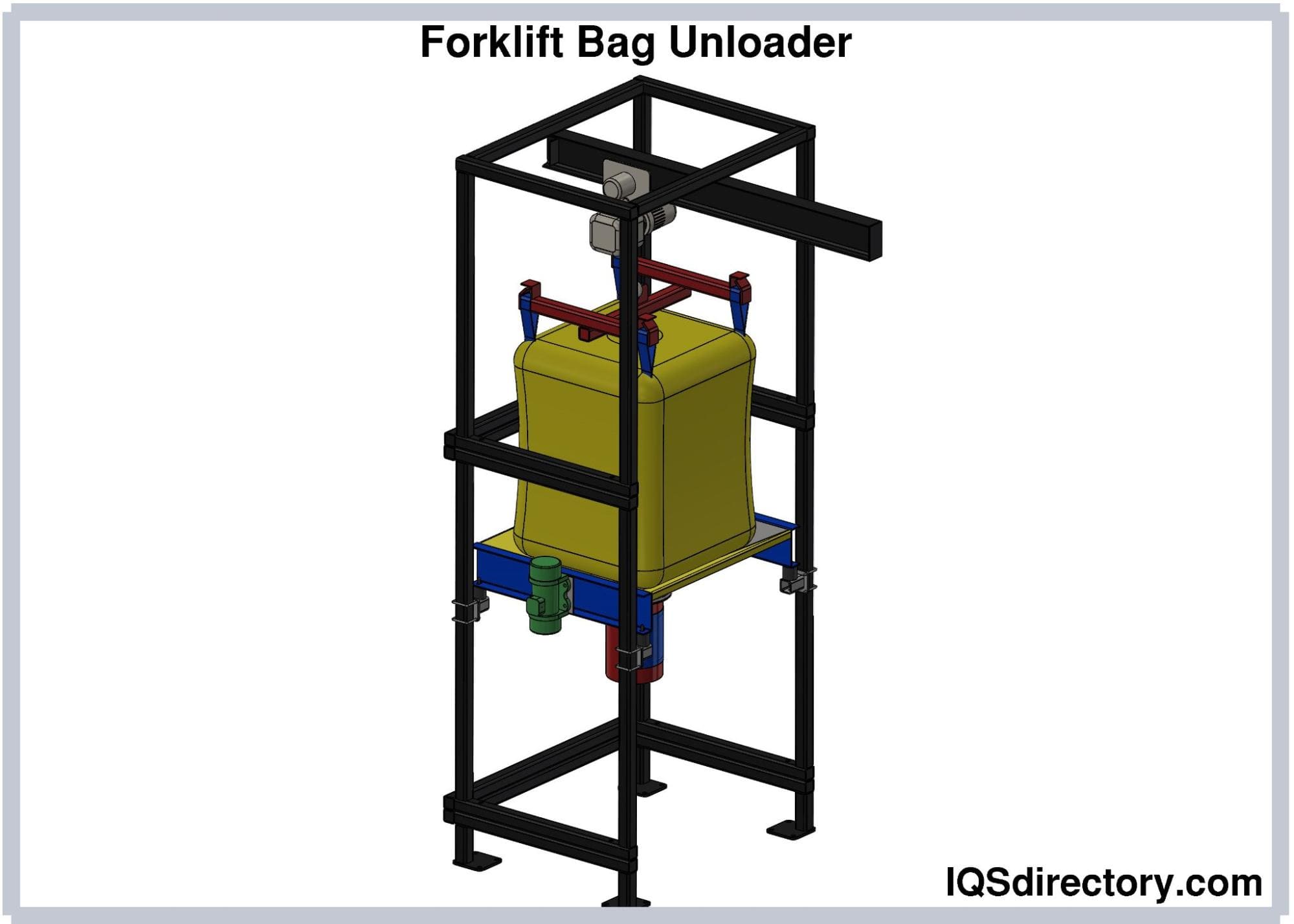

The two most popular frame designs for bulk bag unloaders are forklift-style and chain hoist-style. However, bulk bag unloaders can have many different frame designs.

Forklift-Style

These unloaders have slots that make it simple for a forklift to unload bulk bags. In addition, this bulk bag unloader is frequently shorter than a chain hoist-style bulk bag unloader since it does not need an upper framework to lift or position the bags.

Chain Hoist-Style

These unloaders integrate a pneumatic or electrically-powered hoist that enables an operator to raise, position, and support the bag for unloading, enabling the unloading of the bags without using a forklift.

Crane-Style

Bulk bag unloaders in this design are a less common choice. Similar to how a forklift is used to load bulk bags, a crane-style bulk bag unloader is used to operate a crane to unload bags.

Bulk Bag Unloader Components

Bulk bag discharger systems are made to work hard in demanding situations. Unlike the bolt-together unloader designs prevalent in the market, every bulk bag discharge system, independent of its particular design or application, functions on a process-specific, fully-welded structural framework chassis. The conventional bulk bag unloader has a lifting frame with safety hooks, movable handling supports, and an aspiration point to remove displaced air, which enables the system to balance air flow and regulate dust.

A typical agitation system will have a delay between each paddle as the agitation paddles energize one at a time. The paddle activity continues until the bag is empty or a flow detection sensor detects no flow. When the material has become lumpy inside the bulk bag due to transportation compaction, a lump breaker is used to "resize" the product to a specific particle size. Frame construction using painted mild steel is common. There are additional frames made of stainless or galvanized steel.

Benefits of a Bulk Bag Unloader

Decreased Strain on Resources

Less labor is required to perform unloading duties since bulk bag unloaders collect and distribute material into processing lines. This is a big advantage for facilities with a limit on worker resources.

Reduced Dust and Product Loss

Bulk bag unloaders provide a dust-free discharge procedure for sealing in powder ingredients, reducing product loss during dispensing, and improving worker comfort and safety.

Improved Sanitation

Bulk bag unloaders are also intended to enhance hygiene. As a result, products only make contact with the inside of a bag liner. This provides greater cleanliness and product protection.

Boosted Productivity

Since bulk bag unloaders perform heavy lifting, operators may load, tie, untie, and remove bags without reaching into awkward or hard-to-reach spaces. Unloaders also feature user-friendly, simple to understand, control screens so an operator can be rapidly educated on how to use this machinery.

For applications where bulk bag heights are more uniform, or the material properties of the bagged product are more consistent, meanwhile, the fixed-height ram positioning feature provides full conditioning while reducing bag conditioning cycle times.

Improved Safety and Material Delivery

They improve material delivery uniformity downstream and eliminate the safety risks associated with manual bag conditioning processes.

Adaptable Placement Positions

The bulk bags' heights, and their bag conditioning cycles and sequences, frequently differ. A feature known as vertical-travel ram placement positions the rams on some bulk bag conditioners at a specific height where they are most needed. The vertical-travel ram design eliminates turntable and scissor-lift deck issues.

Conclusion

Large bags of bulk material can be quickly and efficiently unloaded with bulk bag unloaders. These machines are used in numerous industries, including mining, agriculture, and food production. These unloaders meet all national and international hygiene standards. This standard indicates that offloading large items is now more hygienic and secure. Many bulk bag unloader businesses have recently developed new designs for bag unloading, primarily for the processing and packaging sectors of the pharmaceutical food industries. Integrated automation maximizes uptime availability in the food and pharmaceutical processing to achieve this.

Choosing the Correct Bulk Bag Unloader Supplier

To make sure you have the most beneficial outcome when purchasing bulk bag unloaders from a bulk bag unloader supplier, it is important to compare at least 4 companies using our list of bulk bag unloader suppliers. Each bulk bag unloader supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each bulk bag unloader company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple bulk bag unloader companies with the same message.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

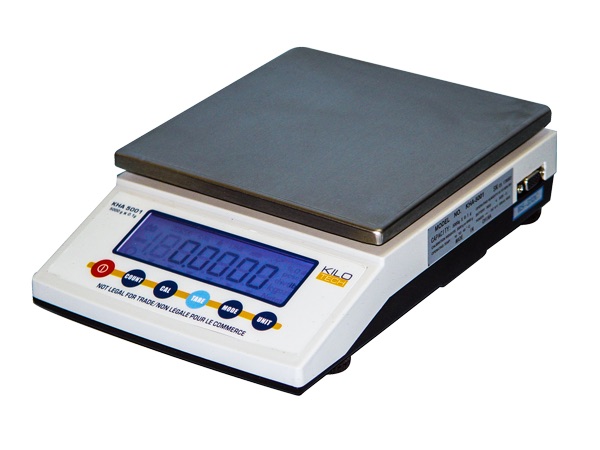

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services