Bulk bags, also called “flexible intermediate bulk containers” (FIBCs), are useful when transporting bulk materials. They are easy to lift using their loops, store on pallets, and move to their destinations. Read More…

VAC-U-MAX is a premier custom pneumatic conveyors manufacturer of support equipment for conveying, batching and weighing materials. With our system your company’s product can move gently and quickly from point to point, with nothing in the way to impede the efficiency of its movement. Contact VAC-U-MAX today so they can find the perfect product for you.

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry.

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

At ENTEK, we are a dynamic team of experts specializing in pneumatic conveyors, dedicated to providing innovative solutions that streamline material handling processes for a wide range of industries. With a proven track record of excellence and a commitment to customer satisfaction, we have established ourselves as a trusted partner for clients seeking efficient and reliable conveying solutions....

More Bulk Bag Equipment Manufacturers

However, loading bulk bags is a challenging task. Filling them up by hand is hard and may lead to spills. Therefore, specialized automated filling machines are often necessary to carry out the work quickly and effectively.

Considerations When Choosing a Bulk Bag Equipment

The business's unique requirements must be evaluated when purchasing bulk bag loading equipment. The factors below must be considered:

- Whether the bulk loading equipment fits into the facility

- Whether the equipment meets the planned budget

- Whether the loader will efficiently carry the materials needed for transportation

- What types of materials need transportation

- How far different products need to be transported

- How many bags are filled every day

- Whether there is already an efficient moving system operating

- Whether there are rigorous standards to be met, like sanitary requirements

Types of Bulk Bag Equipment

The different types of bulk bag equipment include:

Stand-Alone Fillers

These are the most popular mechanized type of bulk bag filler. These fillers have a straightforward design and are intuitive and user-friendly to operate. They are also adaptable enough to work in various industries and applications.

These bulk loaders rely on gravity. The filler is placed above the bulk bag and directly deposits material into the bag below using a discharge hose. Often, workers can calibrate the flow of material. The filler can release large volumes quickly to fill bags. It can also release a slow dribble if the bag must hit a precise weight.

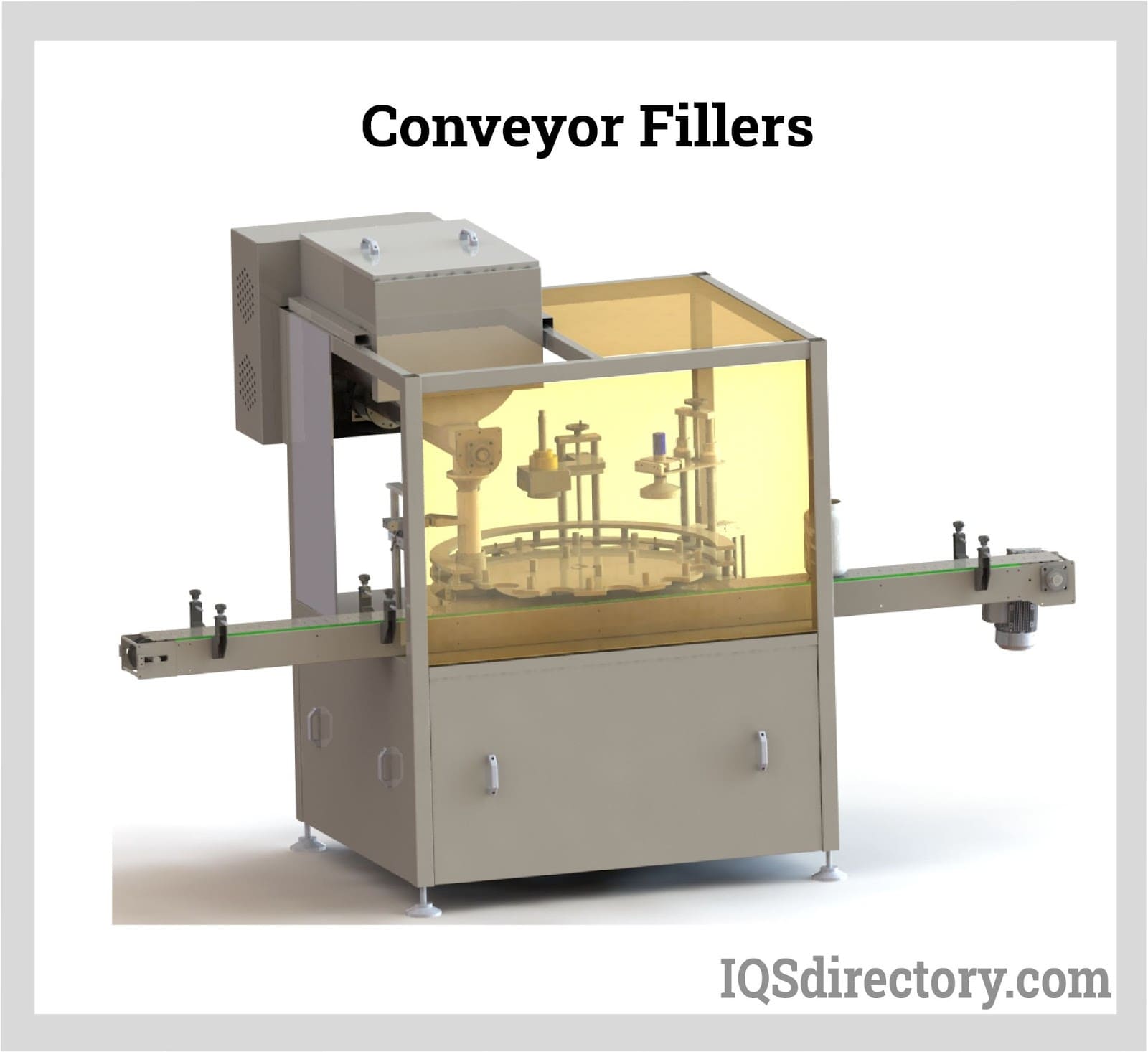

Conveyor Fillers

Conveyor fillers can move products both vertically and horizontally, while stand-alone fillers move products only vertically. Conveyor fillers act like a conveyor belt as an extra to a loader. They can mobilize the necessary materials from ground level or any location in the facility into the loader and then into the bulk bags.

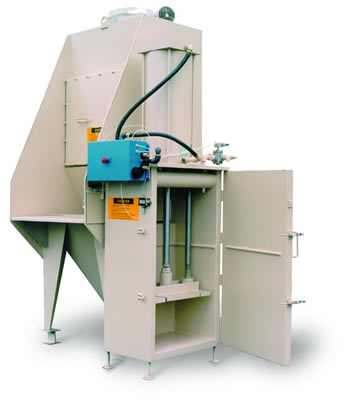

Conveyor fillers come in different styles. The easiest of those are the flexible screw conveyors. Flexible screw conveyors operate best if the facility makes a dumping site at the floor level and gathers the necessary material there. The flexible screw conveyor moves the materials from the dumping site into the bulk loader, then releases the materials from the loader into the bulk bag using a spout over the bag.

More advanced alternatives for conveyor fillers include modular tubular fillers. These fillers are much more complicated than flexible screw conveyors. They are often customized to a particular factory, using exact information of the factory layout to transport material and pour it into bulk bags.

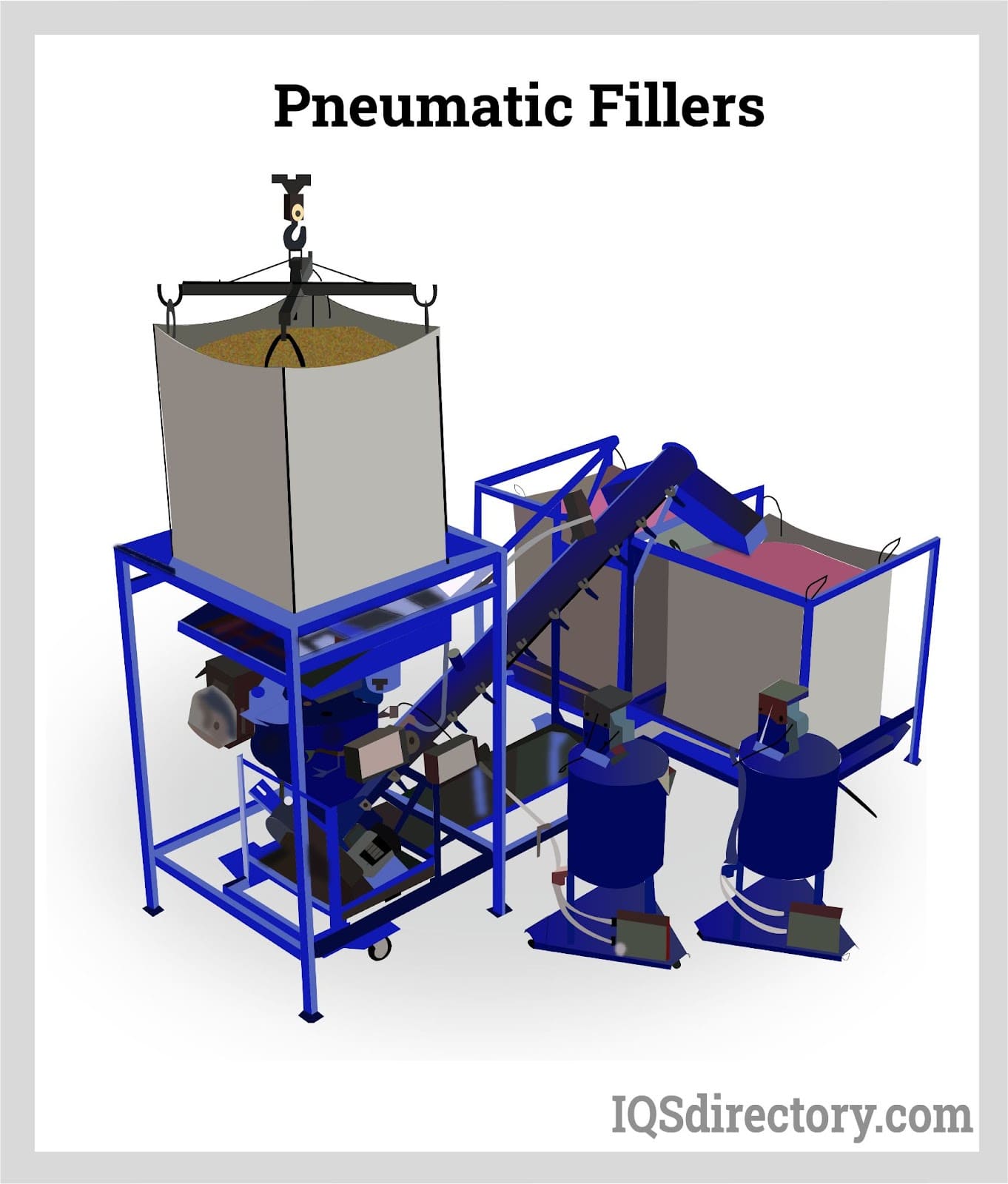

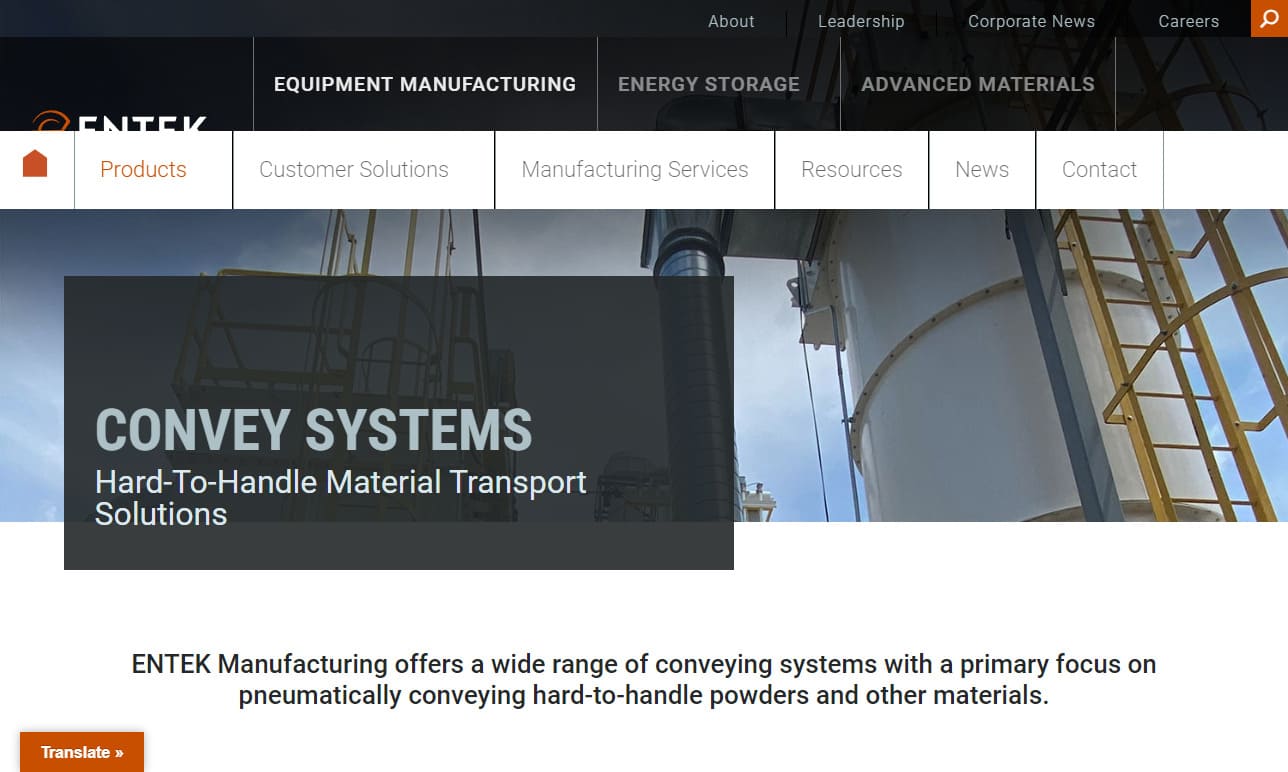

Pneumatic Fillers

Pneumatic systems for bulk bag loading provide the most sophisticated, inclusive, and rugged solution. They are best suited for large-scale operations, although they can sometimes be beneficial in small spaces.

Pneumatic systems can move enormous quantities of various materials, and they're designed to transport those materials all around a facility and finally into waiting bulk bags. They use heavy-duty vacuum systems and industrial-strength pressurized blowers to manage great quantities of heavy materials with simplicity.

Pros and Cons of Bulk Bag Equipment

Here are a few of the pros and cons of these bulk bag loading equipment:

Stand-Alone Fillers Pros and Cons

Stand-alone fillers are condensed, versatile, and simple to use. They work very well for facilities that already have conveyor lines or other transportation systems and only need to add supporting equipment. However, they aren't quite suitable for bigger facilities with more complicated demands. They also provide a more restricted service since they can passively release materials downward but can't actively move them from one place to another.

Conveyor Fillers Pros and Cons

Conveyor fillers are more inclusive compared to stand-alone fillers. They offer the benefits of two systems in one. They come with various designs to help meet different factory needs. They are safer to use since they do not have to be filled from above. However, conveyer fillers aren't as straightforward to use as stand-alone fillers and may not fit into smaller plants. They also do not provide the complex array of proficiencies of pneumatic systems.

Pneumatic Fillers Pros and Cons

They are excellent for usage in operations where sanitation is a high priority, like food processing services. Pneumatic fillers are usually fully enclosed; hence they are highly active in keeping pollutants out of the transported material. They are also very dependable and easy to maintain. They offer great prospects for customization fitting a particular operation's requirements.

However, this equipment can be bulky and might not fit in small or medium-sized spaces. In addition, they are difficult to use and might not offer a lot of return on investment for facilities that need to fill small quantities of bags or use limited materials.

Choosing the Right Bulk Bag Equipment Manufacturer

To make sure you have the most positive outcome when purchasing bulk bag equipment from a bulk bag equipment manufacturer, it is important to compare at least 5 manufacturers using our bulk bag equipment directory. Each bulk bag equipment manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each bulk bag equipment business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple bulk bag equipment businesses with the same form.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

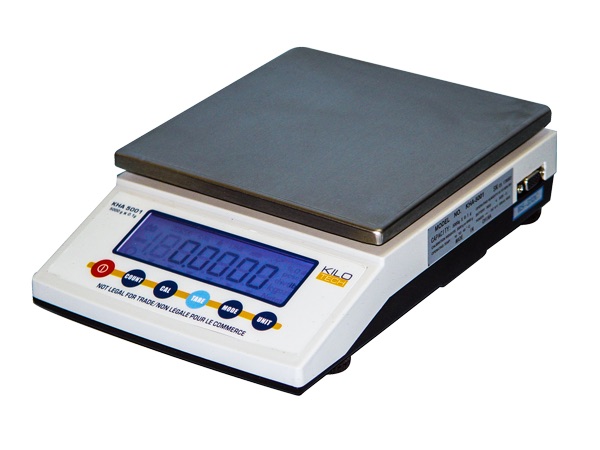

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services