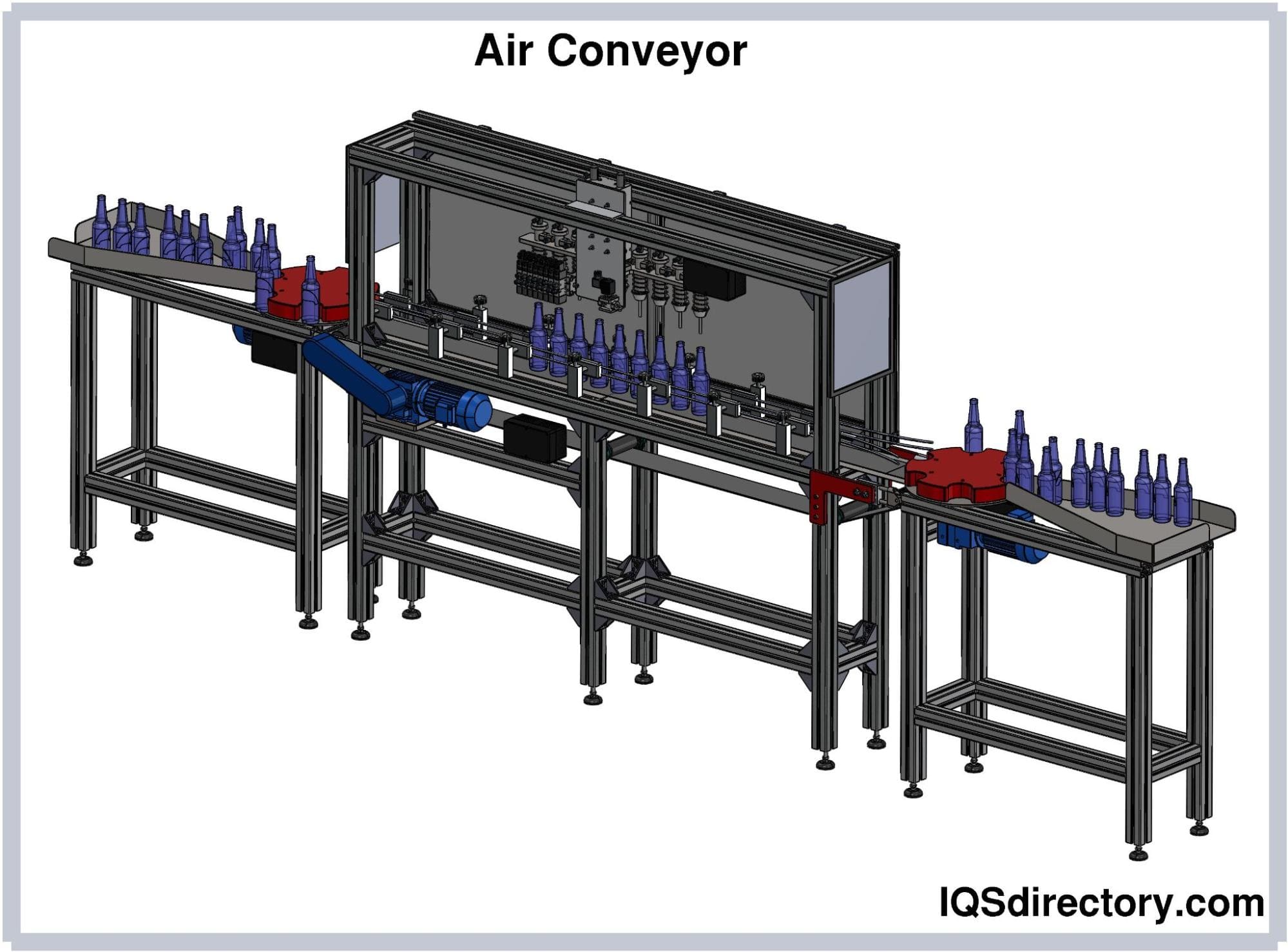

Air conveyors are most frequently employed to move soft goods like empty containers, boxes, and trays. A class of equipment known as an “air conveyor” uses air to transport goods and materials rather than mechanical belts or chains with speeds frequently reaching 1,000 fpm. They are not, however, just used with lightweight materials. Instead, materials-handling devices called air conveyors transport various things using pressurized air. Read More…

VAC-U-MAX is a premier custom pneumatic conveyors manufacturer of support equipment for conveying, batching and weighing materials. With our system your company’s product can move gently and quickly from point to point, with nothing in the way to impede the efficiency of its movement. Contact VAC-U-MAX today so they can find the perfect product for you.

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry.

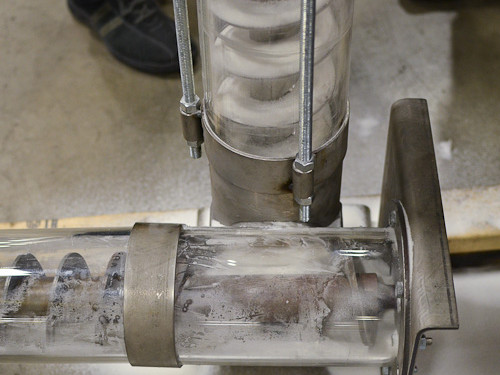

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

At ENTEK, we are a dynamic team of experts specializing in pneumatic conveyors, dedicated to providing innovative solutions that streamline material handling processes for a wide range of industries. With a proven track record of excellence and a commitment to customer satisfaction, we have established ourselves as a trusted partner for clients seeking efficient and reliable conveying solutions....

More Air Conveyor Manufacturers

They can be found in companies that produce and sell vast quantities of goods and, as a result, require machinery to help move those goods from one location to another quickly and effectively. These devices are also known as pneumatic conveyors.

Operational Principles of Air Conveyors

The earliest air conveyors consisted of a pipe with a blower attached to one end. Items like sawdust would be driven through the pipe by the air and enter the conveyor through a T-fitting or opening just downstream of the blower. Coal, grain, and scrap conveyors still use the same fundamental technology. Because the objects being carried are in the same plenum or pipe as the air moving them, these are known as internal air conveyors.

Blowers are another frequent type. A blower pressurizes a plenum, and air exits the plenum through various nozzles or louvers that are pointed toward the things to be moved and pushed in that direction. Items transported on these conveyors are typically held within low-friction guides to maintain orientation. The hybrid air conveyor, a less popular variation, uses two plenums. Louvers allow air to pass through to an inner plenum, where objects like scrap metal are moved.

Due to pressure losses inside a pipe, internal air conveyors can only be as long as 100 feet or fewer. Because air enters and exits throughout hybrid conveyors, they can be almost any length. Any friction between the product and air conveyors must be kept to a minimum because the force provided by air momentum imparted to the product is less than that caused by conventional conveyors (belts). Early closed air conveyors moved cargo via a smooth pipe, and an air boundary layer on the interior walls achieved minimal friction.

Types of Air Conveyors

Different air conveyors can be identified based on how they handle objects.

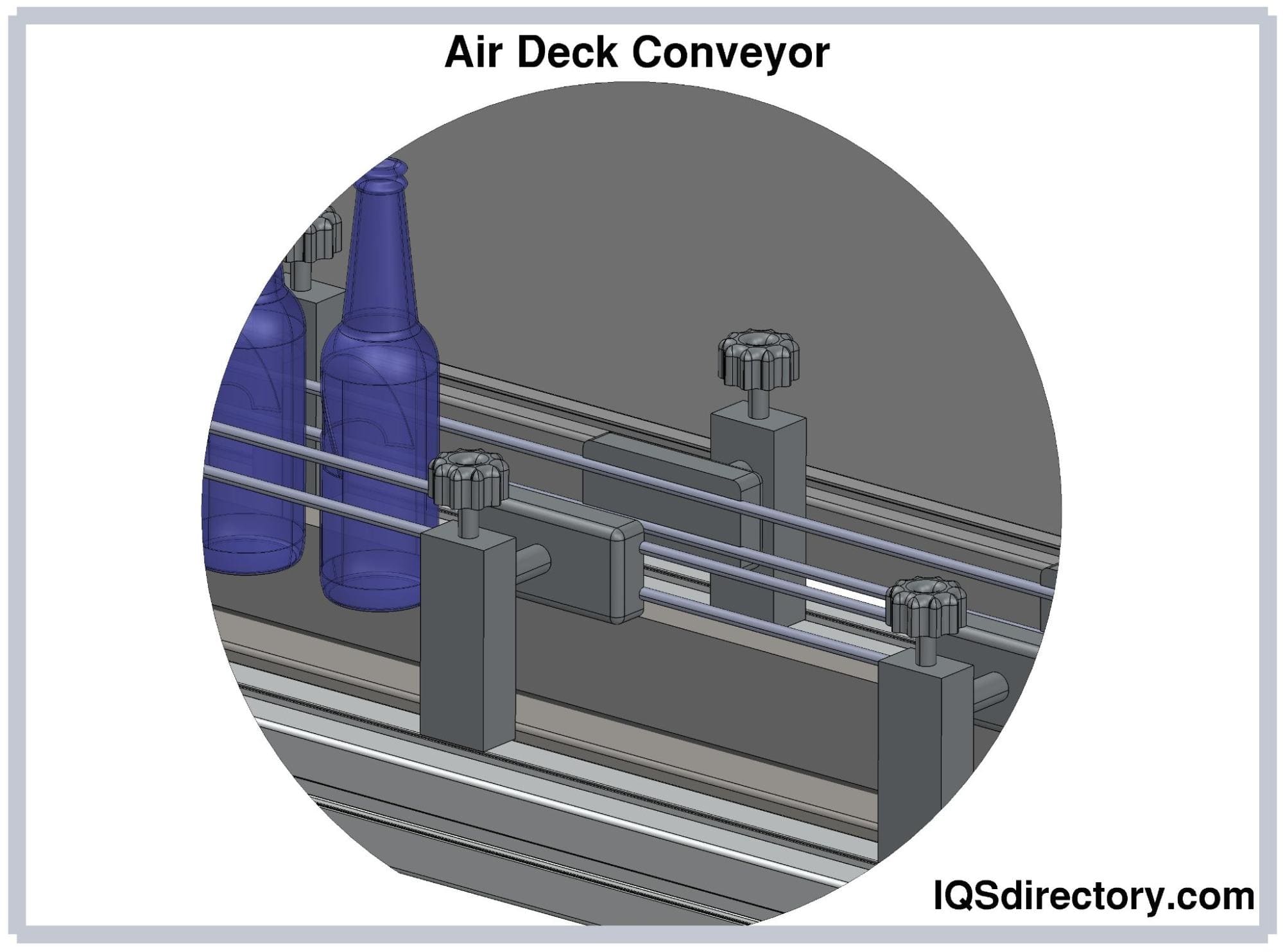

Deck Conveyors

Deck conveyors attempt to lift products off the conveying surface but do not succeed—these transport items like cans, caps, and cartons or cases. Deck conveyors function similarly to air hockey tables, but in addition to the lifting holes, they also have directional louvers that direct the product's motion. Deck conveyors frequently have an angle of more than 10 degrees, and specialized air deck conveyors known as "tunnel tracks" for cans with decks on the top and bottom occasionally function as vertical elevators.

Deformed bottoms that scrape on the deck and delay or stop flow are sensitive to cartons and cases. Products transported on deck conveyors must rest uniformly on one side against the lifting apertures and louvers. If not, the product can vent the entire air intended to float it. A guide is typically needed to prevent products from toppling over. Typically, a top guide that is flat and parallel to the bottom surface is employed.

Neck Ring Conveyors

Plastic bottle neck ring conveyors transport bottles along a rail while capturing bottles by the ring (the region of the bottle just below the threaded portion the cap screws into). The conveyor's length is run by two low-friction tracks parallel to one another and placed side by side, similar to a train track.

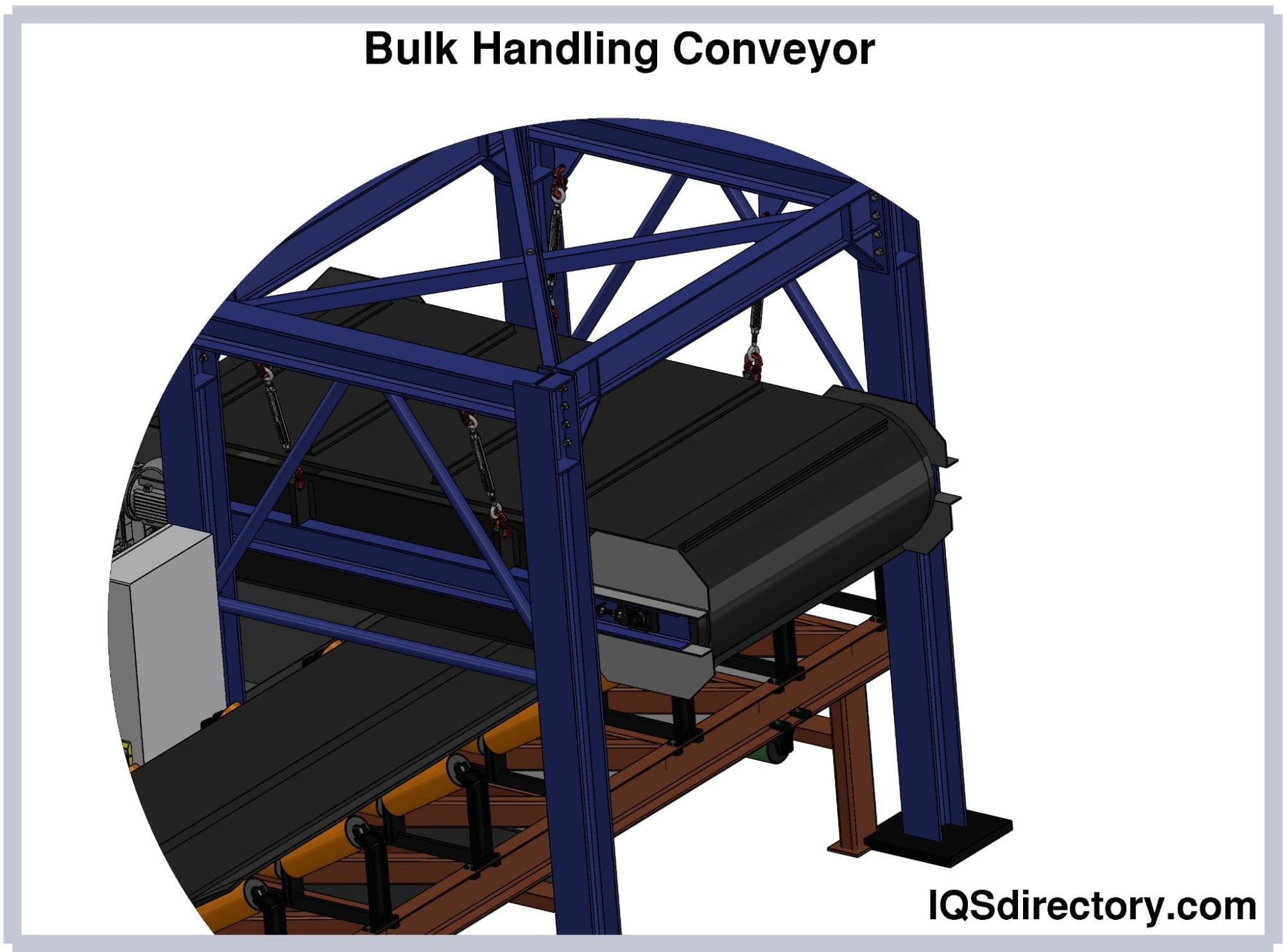

Bulk Conveyors

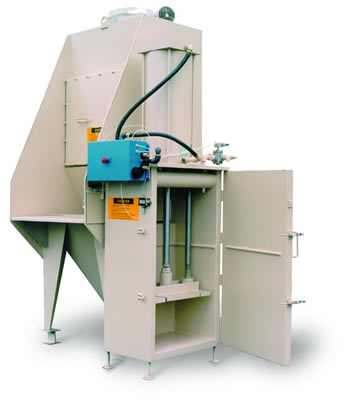

The oldest application of air conveyors is likely to be bulk conveyors. Conveyors for simple bulk air are nothing more than tubes with blowers on one end. The airstream passing through the tube moves the material. Some bulk conveyors are completely covered, while others, like metal scrap conveyors, include openings on the top or one side. These conveyors employ louvers spaced regularly to keep the scrap stream moving. Bulk conveyors transport grains, bottle tops, powders, scrap, and coal.

Benefits and Drawbacks of Air Conveyors

Air conveying is a very dependable technology that can help a business save time and money and handle a wide range of materials. Asbestos, hazardous waste, wood chips, plastics, food, textiles, chemicals, gravel, coal, carbon black, metals, rocks, tablets, pellets, pills, sands, soils, grains, and powders are a few examples of these materials. Air conveyors also have some drawbacks, so they could be better. Air conveyors are more energy-intensive and cannot process materials with greater densities or larger particle sizes.

Sticky substances, gravel, and boulders are a few materials that should not be used in an air-conveying system. It is essential to ascertain whether the needed materials can be transported by air. Air conveyors are simple to operate around existing machinery and maintain. Due to all these features, air conveyors are a smart investment for a materials handling company. An experienced air conveyor manufacturer will help you locate the best suits for your application.

Applications of Air Conveyors

Air conveyor systems are employed for bulk handling of items in huge numbers, such as powders and food. They are among the most frequently used conveyor systems and come in various designs. In some situations, processing these materials by hand by employees is a more economical choice. However, it is far more advantageous for a machine to undertake this work in larger-scale manufacturing scenarios. Manufacturing procedures like assembly and packing lines would only be possible using conveyor systems. Mining, glass manufacturing, textile production, powder coating services, aviation and watercraft manufacture, pharmaceutical product research, plastic fabrication, and food and beverage processing are some industries that use air conveyors.

Choosing the Correct Air Conveyor Company

To make sure you have the most productive outcome when purchasing air conveyors from an air conveyor company, it is important to compare at least 4 to 5 companies using our air conveyor directory. Each air conveyor company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each air conveyor company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple air conveyor companies with the same message.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

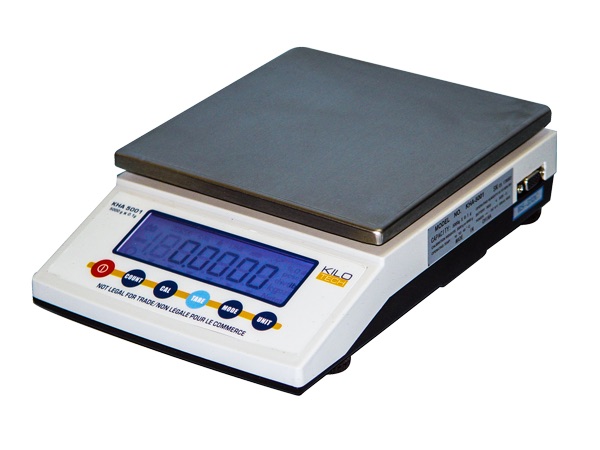

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services